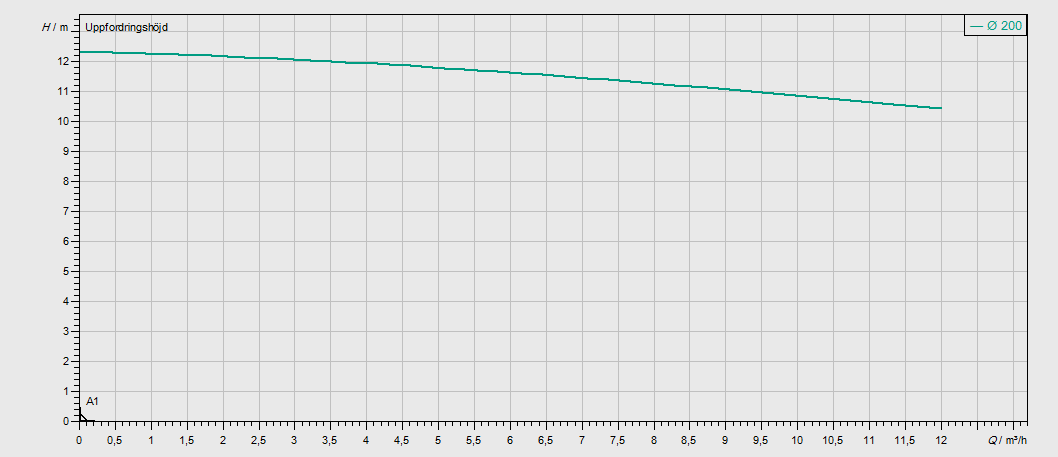

Existing pump - Circulation Pump curve

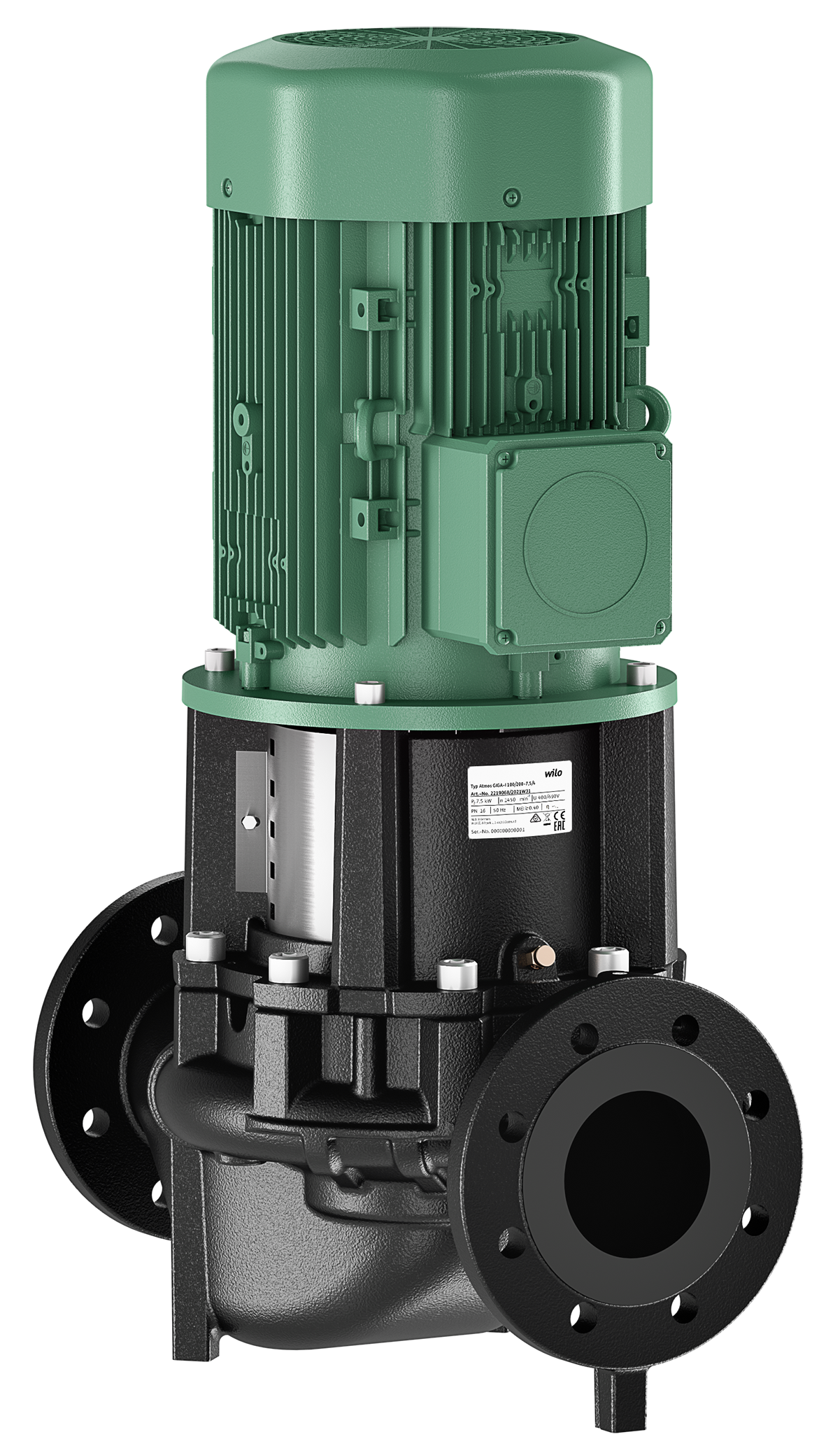

Replacement pump - Conventional Exchange sheet

Comment

Product information

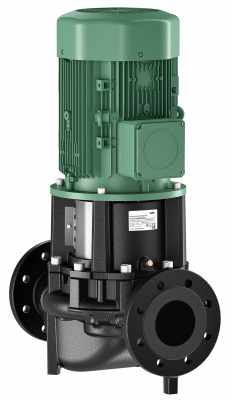

Atmos GIGA-I 40/160-0,75/4

Design

Glanded pump in in-line design with flange connection.

Application

The pumping of heating water (in accordance with VDI 2035), chilled water and water-glycol mixtures without abrasive substances in heating, chilled water and cooling systems.

Technical data

- Permitted temperature range of the fluid: -20 °C to +140 °C

- Max. ambient temperature 40 °C

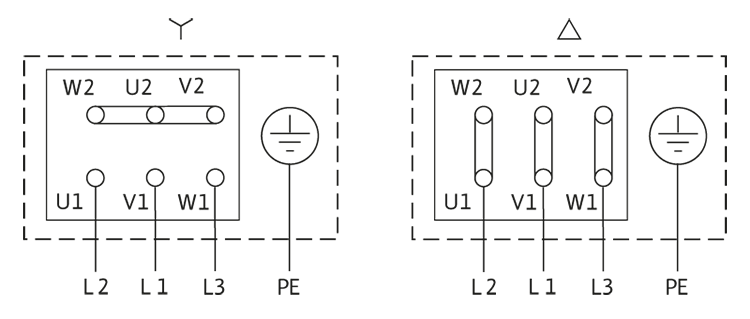

- Mains connection 3~400 V, 50 Hz (others on request)

- Protection class IP55

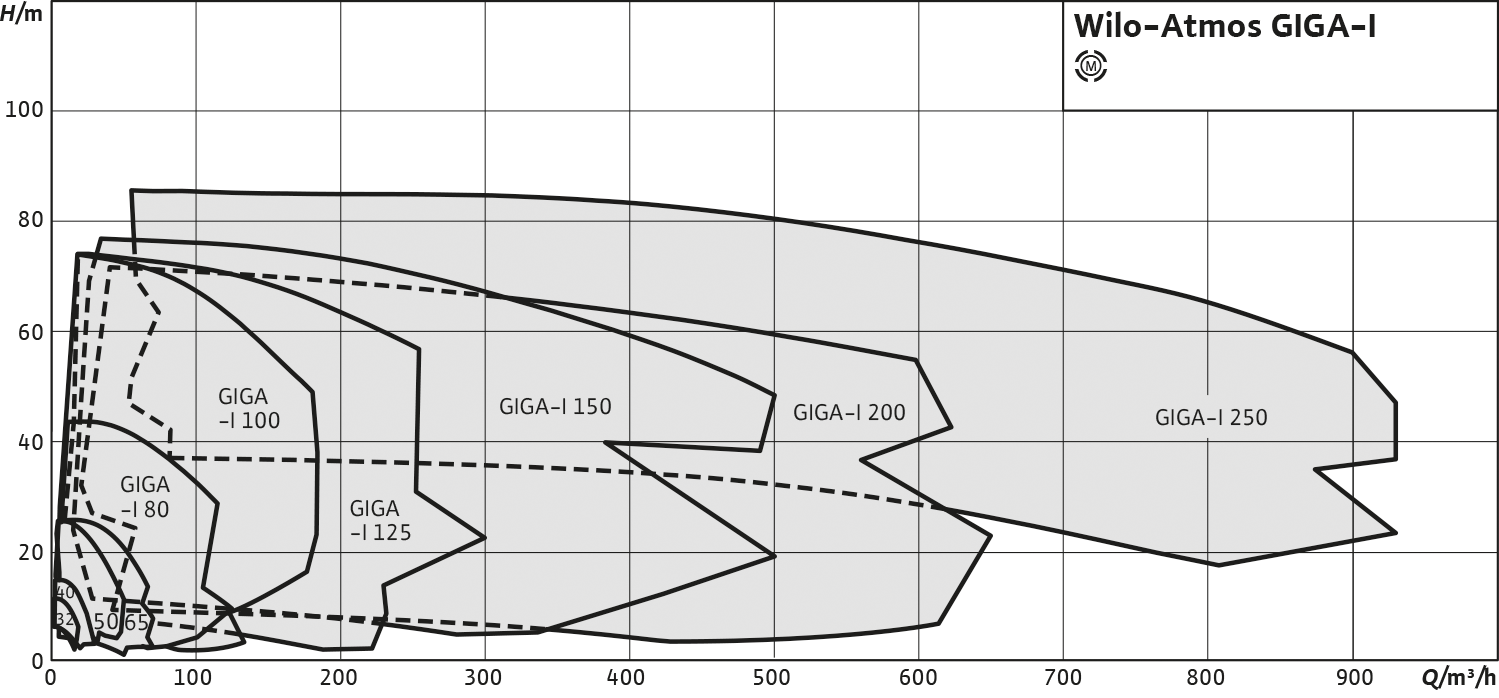

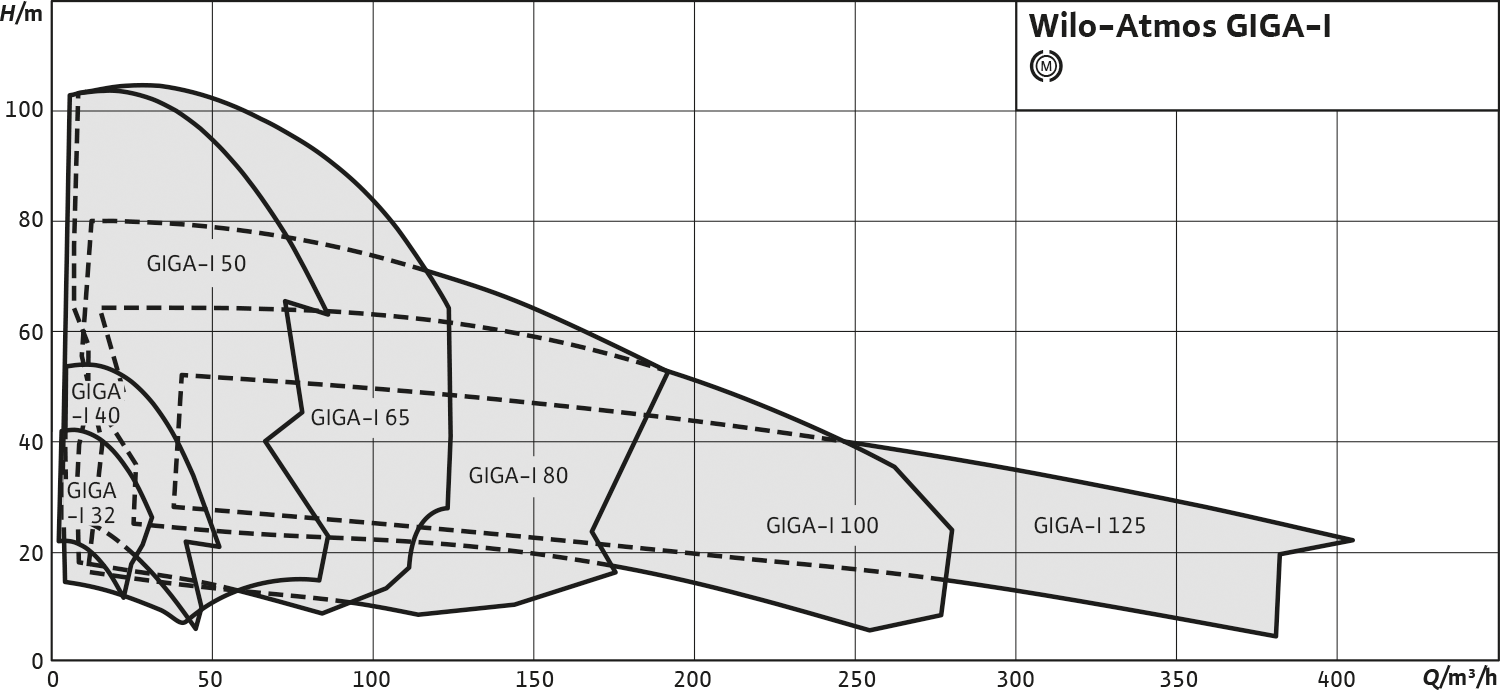

- Nominal diameter DN 32 to DN 250

- Standard version for operating pressure: 13 bar (up to +140 °C) / 16 bar (up to +120 °C)

- Pump housing and lantern: Standard: EN-GJL-250;

- Impeller: Standard: EN-GJL-200; special version: Bronze CuSn 10 stainless steel 1.4408

- Shaft: 1.4122

- Mechanical seal: AQEGG; other mechanical seals on request

Single-stage, low-pressure centrifugal pump in in-line design with:

- Mechanical seal

- Flange connection with pressure measuring connection R 1/8

- Lantern

- Coupling

- IEC standard motor

- Pump

- Installation and operating instructions

- Made of steel.

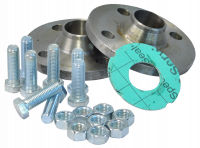

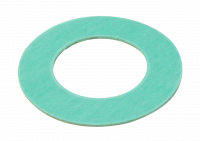

- Counter flanges (weld) are delivered complete (in pairs) with bolt, nut and flange gasket.

- Thickness: 2 mm.

- Inner diameter: 49 mm.

- Outer diameter: 85 mm.

Automatic reactivation of pump after power failure and automatic fault acknowledgement after cooling off of the motor.

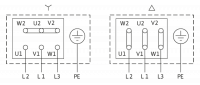

Equipment/function:

- Full motor protection tripping unit for pumps with thermal winding contact (WSK)

- Switch on/off with integrated run signal light

- Terminals for external, potential-free activation/deactivation

- Connection terminal strip

Automatic reactivation of pump after power failure and automatic fault acknowledgement after cooling off of the motor.

Equipment/function:

- Full motor protection tripping unit for pumps with thermal winding contact (WSK)

- Switch on/off with integrated run signal light

- Fault signal light

- Terminals for external, potential-free activation/deactivation

- Potential-free contacts for external run signal (SBM) and fault signal (SSM)

- Connection terminal strip

- Switchgear SK 622N

- 4 threaded cable connections M20

- Installation and operating instructions

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.