Existing pump - Circulation

Replacement pump - Conventional Exchange sheet

Comment

Product information

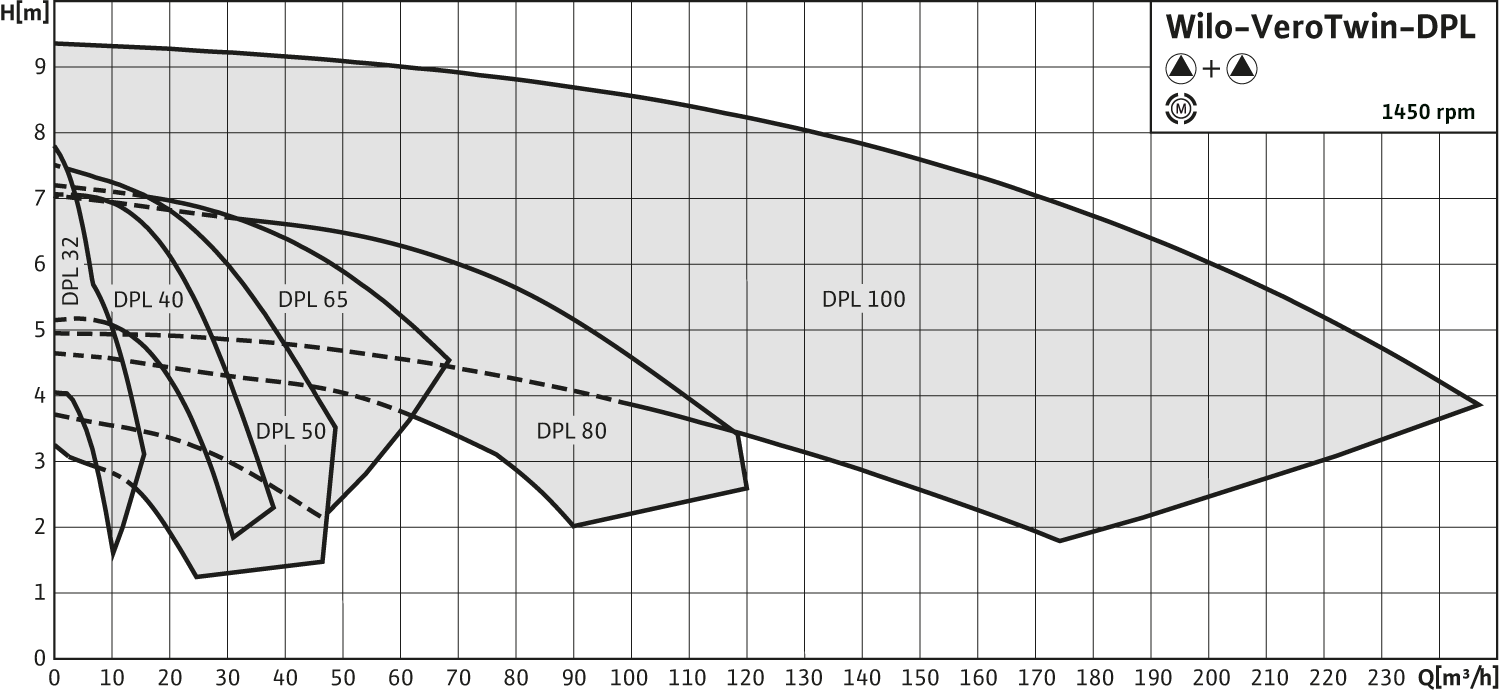

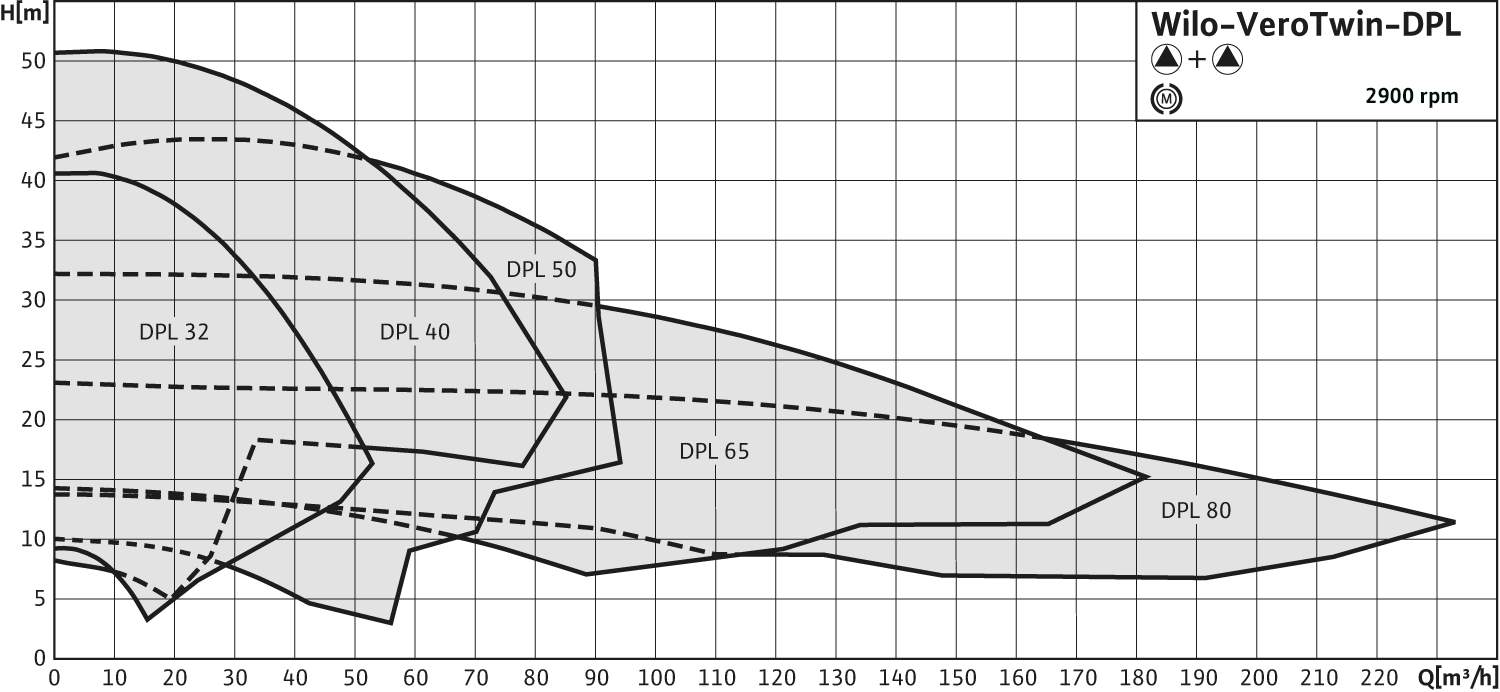

DPL 32/165-4/2

Your advantages

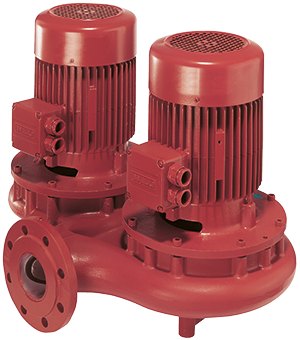

- Reduction of space required and installation costs due to twin-head pump design

- Main/standby mode or peak-load operation (by means of external auxiliary device)

- High standard of corrosion protection thanks to cataphoretic coating

- Series design: motor with one-piece shaft

- Version N: standard motor B5 or V1 with stainless steel plug shaft

Glanded twin-head pump in in-line design with flange connection.

Application

Pumping of heating water (acc. to VDI 2035), cold water and water/glycol mixtures without abrasive substances in heating, cold water and cooling systems.

Scope of delivery

- Pump

- Installation and operating instructions

- Permissible temperature range -20 °C to +140 °C

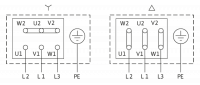

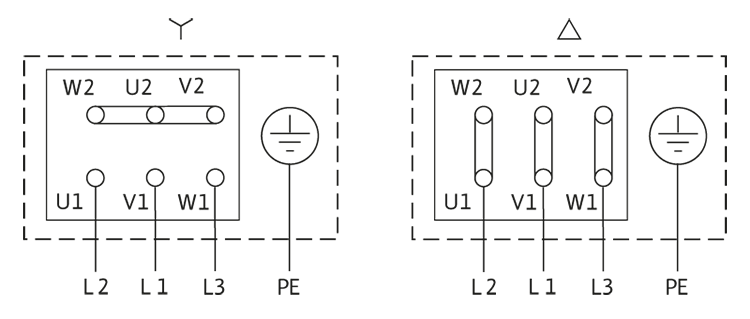

- Mains connection 3~400 V, 50 Hz (others on request)

- Protection class IP 55

- Nominal diameter DN 32 to DN 100

- Max. operating pressure 10 bar (special version: 16 bar)

- Pump housing and lantern: EN-GJL-250

- Impeller: PP fibreglass-reinforced /EN-GJL-200 (depending on pump type)

- Shaft: 1.4021

- Mechanical seal: AQ1EGG; other mechanical seals on request

Single-stage, low-pressure twin-head pump in in-line design with:

- Switchover valve

- Mechanical seal

- Flange connection with pressure measuring connection R 1/8

- Motor with one-piece shaft

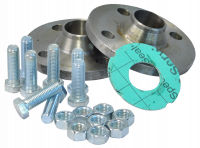

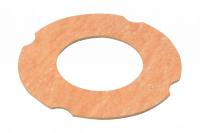

- Comes in a complete kit containing a lid and gasket.

- Made of steel.

- Counter flanges (weld) are delivered complete (in pairs) with bolt, nut and flange gasket.

- Thickness: 1 mm.

- Inner diameter: 43 mm.

- Outer diameter: 82 mm.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.