Existing pump - Circulation

Replacement pump - High Efficiency Standard Exchange sheet

Comment

Product information

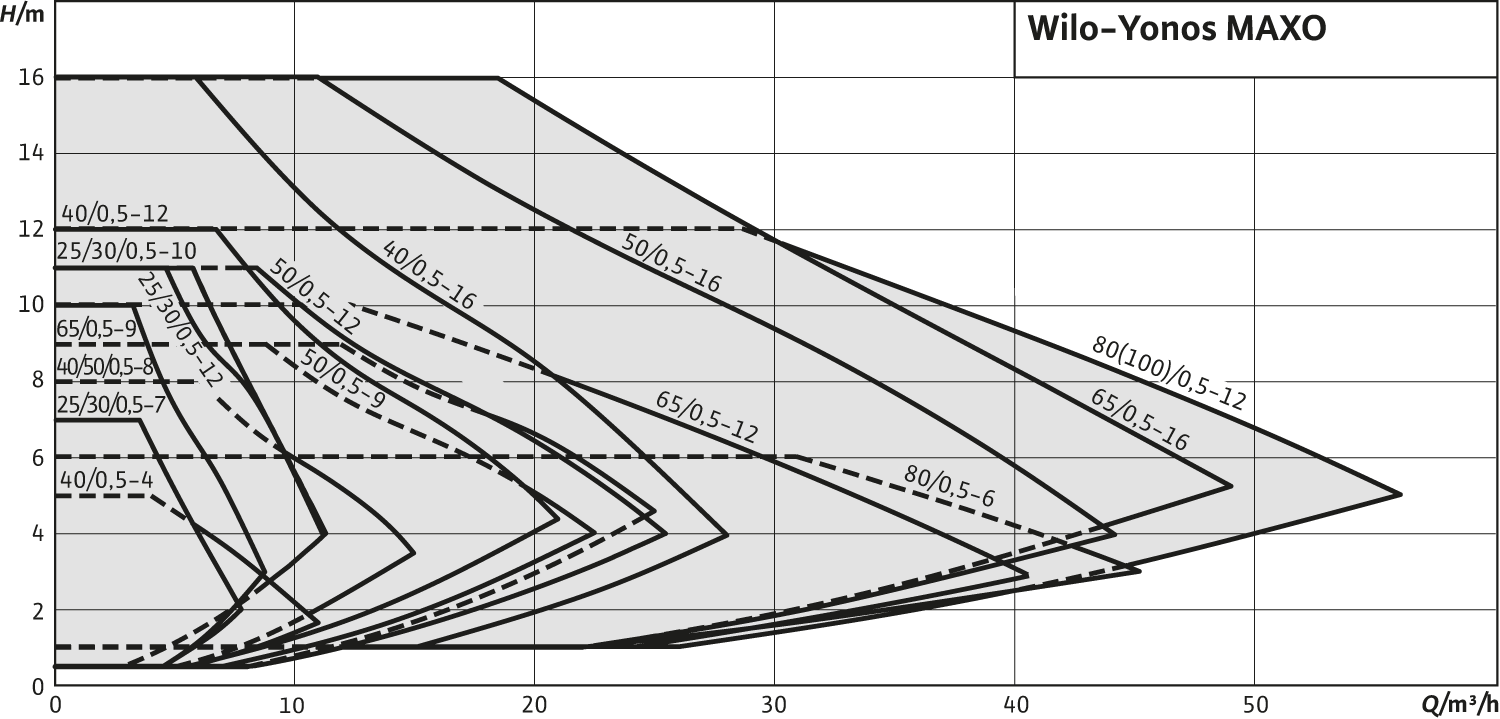

Yonos MAXO 100/0,5-12 PN10

Your advantages

- LED display provides complete transparency of set delivery head, speed stage or possible errors

- Simple adjustment over three speed stages when replacing an uncontrolled standard pump

- Easier electrical connection using the Wilo plug

- System availability ensured via collective fault signal

- Compact design and proven ease of use

Glandless circulator with flange connection, EC motor with automatic power adjustment.

Application

Hot-water heating systems of all kinds, air-conditioning systems, closed cooling circuits, industrial circulation systems.

Equipment/function

Operating modes:

- Δp-c for constant differential pressure

- Δp-v for variable differential pressure

- Setting the operating mode

- Setting of pump output (delivery head)

- Infinitely variable power adjustment according to the operating mode

- Deblocking function

- Soft start

- Integrated full motor protection

- Collective fault signal (potential-free NC contact)

- Fault signal light

- LED segment display for displaying the delivery head and fault codes

- Wrench attachment point on pump body (for threaded pipe union pumps)

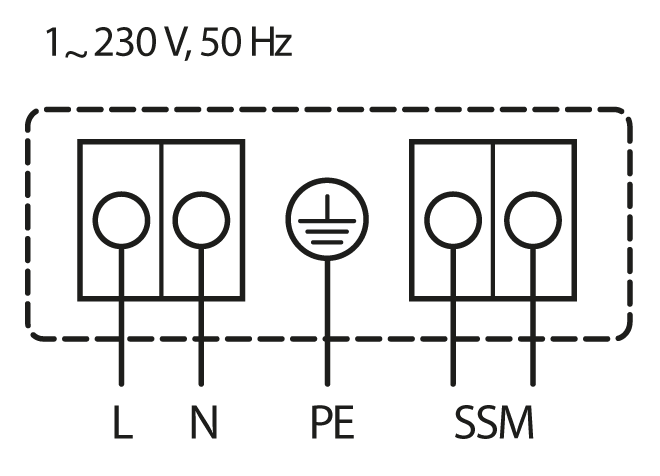

- Quick electrical connection with Wilo plug. For the connection of the mains and SSM lines, with integrated strain relief

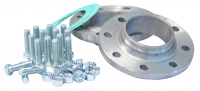

- For flange-end pumps: Flange versions

- Standard version for pumps DN 32 to DN 65: Combination flange PN 6/10 (flange PN 16 acc. to EN 1092-2) for counter flanges PN 6 and PN 16

- Standard version for DN 80/DN 100 pumps: PN 6 flange (designed for PN 16 according to EN 1092-2) for PN 6 counter flange

- Pump

- Incl. washers for flange screws (for nominal connection diameters DN 32 - DN 65)

- Including installation and operating instructions

- Permissible temperature range of -20°C to +110°C

- Mains connection 1~230 V, 50/60 Hz

- Protection class IP X4D

- Flange connection DN 32 to DN 80

- Max. operating pressure of standard version: 6/10 bar or 6 bar (special version: 10 bar)

- Pump housing: grey cast iron with cataphoretic coating

- Shaft: Stainless steel

- Bearing: carbon, metal impregnated

- Impeller: Plastic

- Made of steel.

- Counter flanges (weld) are delivered complete (in pairs) with bolt, nut and flange gasket.

- Thermal insulation of pump housing in heating applications.

- Reduces heat loss by up to 85%.

- Energy saving, reduces operating costs.

- Protects the pump from external damage.

- 100% recyclable.

- Thickness: 2 mm.

- Inner diameter: 115 mm.

- Outer diameter: 152 mm.

The Wilo-Connect module Yonos MAXO is installed on the electronic module of the pump at the position of the Wilo plug.

Utilisation of the Wilo-Connect moduleYonos MAXO dispenses with external contactors and other switchgears as well as the associated installation workload. The load of customer-side switchgears (relays) due to high starting currents is reduced to a minimum by the Connect module Yonos MAXO.

Equipment/function

- Run signal display

- SSM collective fault signal as potential-free NC contact

- SBM collective run signal as potential-free NO contact

- Overriding Off control input (External Off)

- Integrated dual pump management with the functions:

- Main/standby operation with runtime-dependent (24 h) switchover from main to standby pump

- Fault-sensitive switchover to operational standby pump