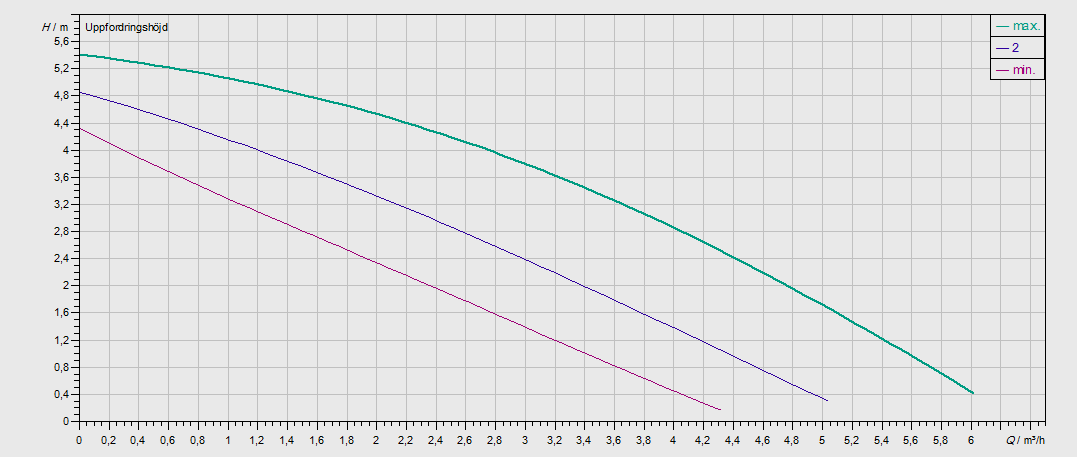

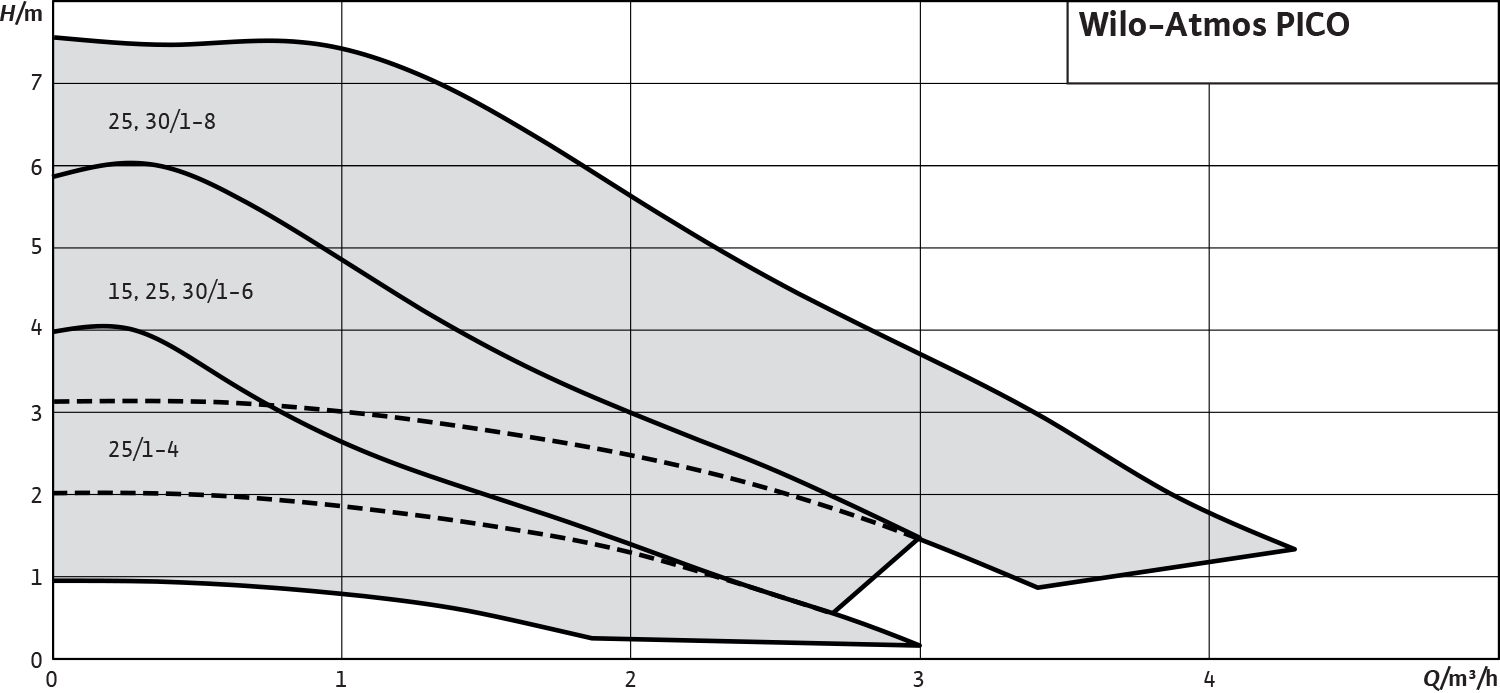

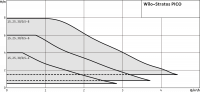

Existing pump - Circulation Pump curve

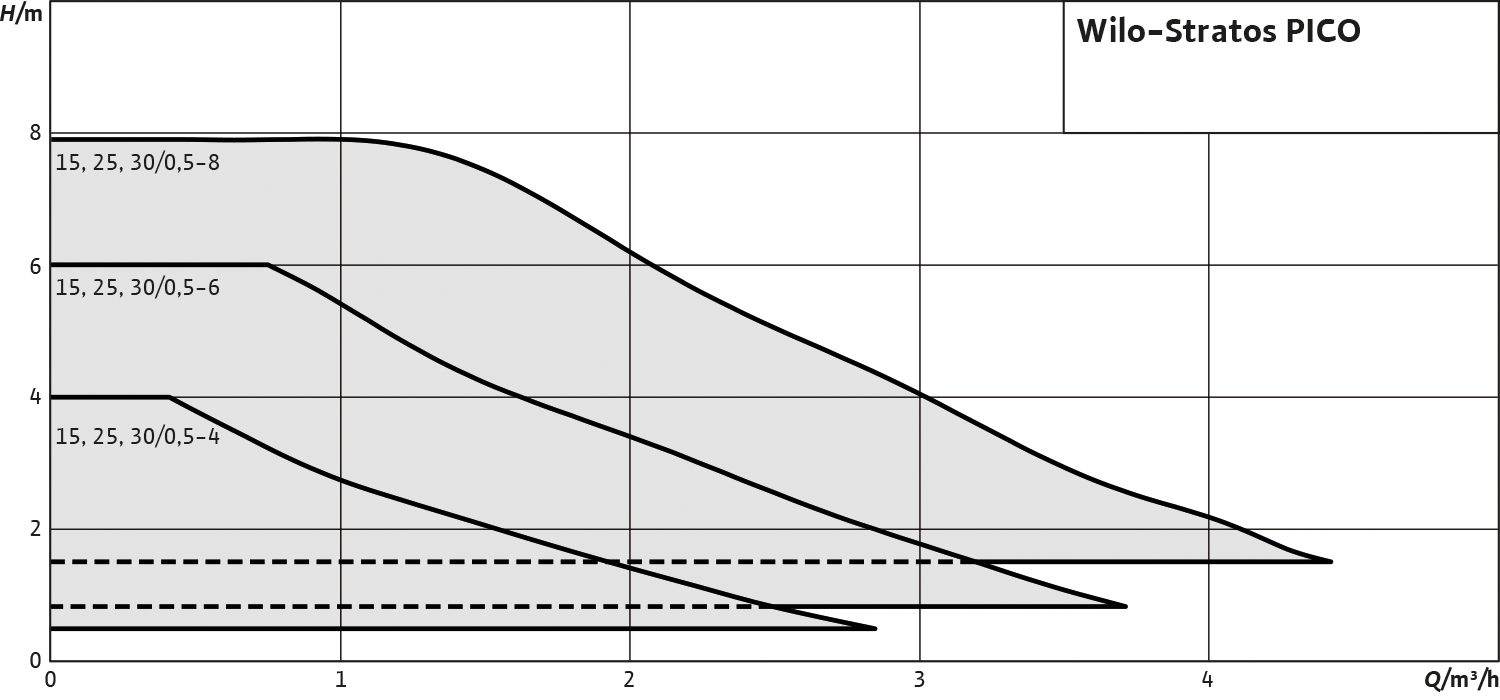

Replacement pump - High Efficiency Premium Exchange sheet

Comment

Product information

Stratos PICO 25/0,5-8 -180

Glandless circulator with screwed connection, blocking-current proof EC motor and integrated electronic power control.

Application

All hot-water heating systems, air-conditioning applications, industrial circulation systems.

Equipment/function

Operating modes:

- Dynamic Adapt plus

- Δ p-c for constant differential pressure

- Δp-v for variable differential pressure

- Constant speed (n-const.)

- Compatible with the Wilo-Smart Balance App

- Setting the operating mode

- Setting of pump output (delivery head)

- Setting automatic setback operation

- Setting automatic operation for pressure-independent valves

- Pump venting

- Manual restart

- Reset function for resetting the electricity meter

- Reset function for resetting to factory settings

- Key lock for disabling the settings

- Continuous power adjustment according to the operating mode

- Automatic setback operation

- Automatic venting function

- Automatic dry-running detection

- Automatic restart

Alternating display:

- Current volume flow

- Current delivery head

- Current speed

- Power consumption

- Energy consumption

- Display status for warning messages (yellow display) and error messages (red display) each with error code and description in plain text

- Pump venting

- Manual restart

- Green LED: Proper operation

- Blue LED: Pump communication with external module

- Wrench attachment point on pump body

- Quick electrical connection with Wilo-Connector

- Automatic venting

- Blocking-current proof motor

- Particle filter

- Thermal insulation as standard for heating applications

- Wilo-Connectivity interface for external modules

- Fluid temperature -10 °C to +110 °C

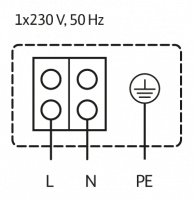

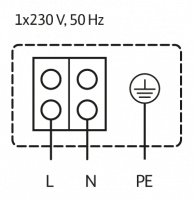

- Mains connection 1~230 V, 50 Hz

- Protection class IPX4D

- Screwed connection G1, G1½, G2

- Max. operating pressure 10 bar

- Pump housing: Grey cast iron with cataphoretic coating (stainless steel: type …-N)

- Thermal insulation: Polypropylene

- Shaft: Stainless steel

- Bearing: carbon, metal impregnated

- Impeller: Plastic

- Pump

- Thermal insulation

- Wilo-Connector

- Gaskets

- Installation and operating instructions

- Fits PICO pumps and Star-Z NOVA.

- Fits PICO pumps and Star-Z NOVA.

- Comes with cable.

- WS8 connector.

- Cable length 2 meters.

interface for building management systems (BMS).

The module is mounted on the electronic module via the Wilo-Connectivity interface of the pump

Equipment/function

- Run signal display

- Analogue input 0 -10 V for setpoint specification

- Run signal display via relay output as changeover contact

- SSM collective fault signal as potential-free NC contact

- SBM collective run signal as potential-free NO contact

-

Control input with configurable functions:

- Override OFF (External OFF), MIN (External MIN), MAX (External MAX)

- 2 PG screwed connections, rotatable with vertical or horizontal orientation

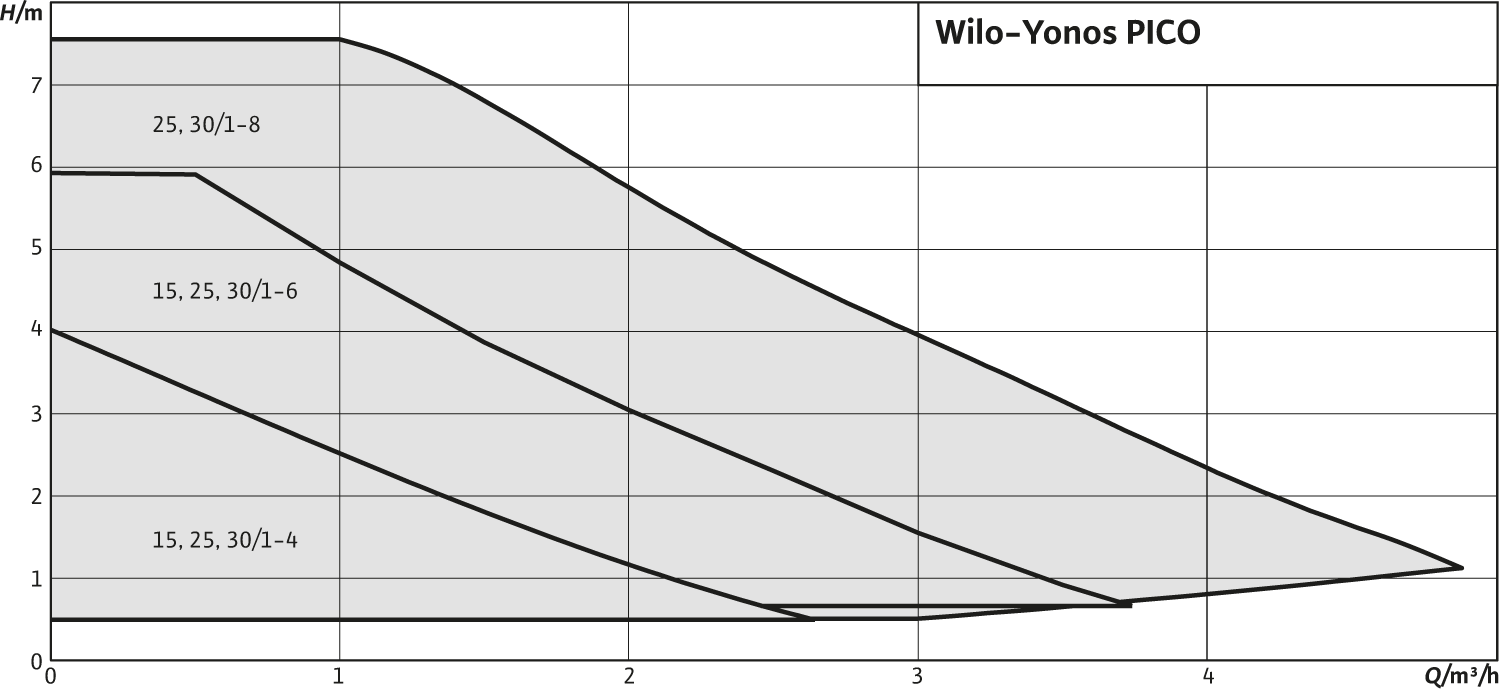

Replacement pump - High Efficiency Standard Exchange sheet

Comment

Product information

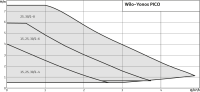

Yonos PICO 25/1-8 -180

Your advantages

- Maximum operating convenience owing to the Green Button Technology with new, intelligent settings, intuitive user interface and new functions

- Optimised energy efficiency owing to EC motor technology, settings with an accuracy of 0.1 m and display of current power consumption

- Quick and easy installation and smooth replacement owing to the new, optimised construction

- Easy maintenance and high degree of operational reliability thanks to automatically and manually triggered restart or pump venting function

- Maximum operational reliability thanks to proven technology

A visible symbol of the new generation of high-efficiency pumps for heating and air-conditioning systems in residential dwellings is the green operating button, which together with new functions provides maximum convenience in commissioning and maintenance. Defaults for radiators or underfloor heating – symbolised by pictograms – save time during commissioning. The energy efficiency was improved once more and the power consumption is thus even lower and always in view. And thanks to the more compact construction, pump replacement is now even easier.

Construction

Glandless circulator with screwed connection, blocking-current proof EC motor and integrated electronic power control.

Application

All hot-water heating systems, air-conditioning applications, industrial circulation systems.

Equipment/function

Operating modes:

- Constant differential pressure

- Variable differential pressure

- Constant speed (3 control pump curves)

- Setting the operating mode in accordance with the application

- Setting of pump output (delivery head)

- Setting the constant speed

- Pump venting function

- Manual restart

- Continuous power adjustment according to the operating mode

- Automatic restart

- Automatic dry-running detection

- Display of power consumption in W

- Display of delivery head for setting

- Display of fault messages (error codes)

- Display of manually activated restart or pump venting function

- Wrench attachment point on pump body

- Quick electrical connection with Wilo-Connector

- Pump venting function

- Manual restart

- Blocking-current proof motor

- Particle filter

- Pump

- Wilo-Connector

- Seals

- Installation and operating instructions

- Fluid temperature -10 °C to +95 °C

- Mains connection 1~230 V, 50 Hz

- Protection class IPX2D

- Screwed connection Rp ½, Rp 1 and Rp 1¼

- Max. operating pressure 10 bar

- Pump housing: Grey cast iron (EN-GJL-200)

- Impeller: Plastic (PP - 40% GF)

- Pump shaft: Stainless steel

- Bearing: carbon, metal impregnated

- Thermal insulation of pump housing in heating applications.

- Reduces heat loss by up to 85%.

- Energy saving, reduces operating costs.

- Protects the pump from external damage.

- 100% recyclable.

- Fits PICO pumps and Star-Z NOVA.

- Fits PICO pumps and Star-Z NOVA.

- Comes with cable.

- WS8 connector.

- Cable length 2 meters.

Replacement pump - High Efficiency Standard Exchange sheet

Comment

Product information

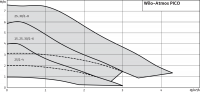

Atmos PICO 25/1-8 -180

Glandless circulator with screwed connection, blocking-current proof EC motor and integrated electronic power control.

Application

All hot-water heating systems, air-conditioning applications, industrial circulation systems.

Equipment/function

Operating modes

- Variable differential pressure (3 pre-defined characteristic curves)

- Constant speed (3 speed stages)

- Setting the operating mode

- Setting of pump output (characteristic curve)

- Setting the constant speed

- Automatic restart

- Display of selected control mode

- Display of selected characteristic curve in the control mode

- LED is lit up in green in normal operation

- LED lights up/flashes in the case of a fault

- Wrench attachment point on pump body

- Wilo-Connector

- Blocking-current proof motor

- Particle filter

- Fluid temperature -10 °C to +95 °C

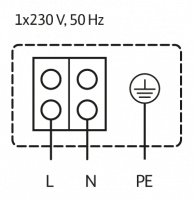

- Mains connection 1~230 V, 50 Hz

- Protection class IPX2D

- Screwed connection G1, G1½, G2

- Max. operating pressure 10 bar

- Pump housing: Grey cast iron (EN-GJL-200)

- Impeller: Plastic (PP - 40% GF)

- Pump shaft: Stainless steel

- Bearing: carbon, metal impregnated

- Scope of delivery

- Wilo-Connector

- Seals

- Installation and operating instructions

- Thermal insulation of pump housing in heating applications.

- Reduces heat loss by up to 85%.

- Energy saving, reduces operating costs.

- Protects the pump from external damage.

- 100% recyclable.

- Fits PICO pumps and Star-Z NOVA.

- Fits PICO pumps and Star-Z NOVA.

- Comes with cable.

- WS8 connector.

- Cable length 2 meters.

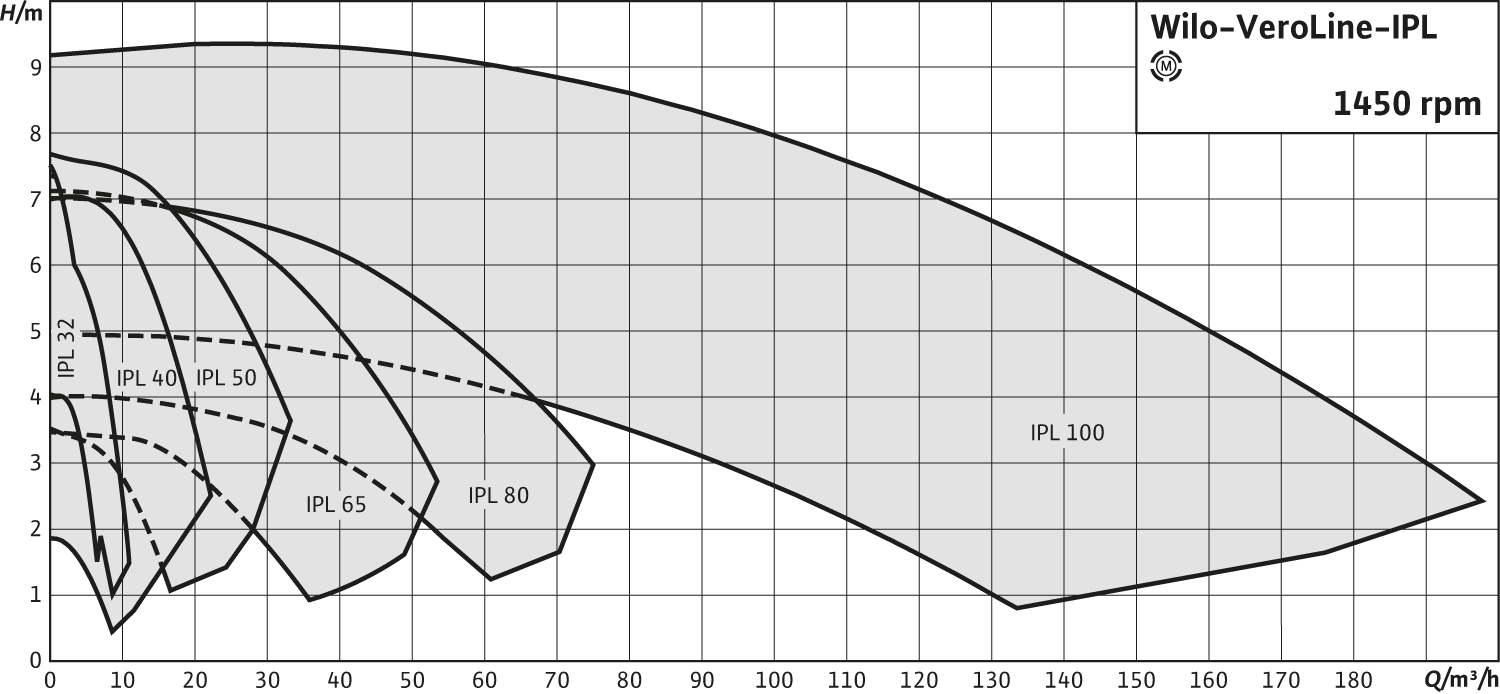

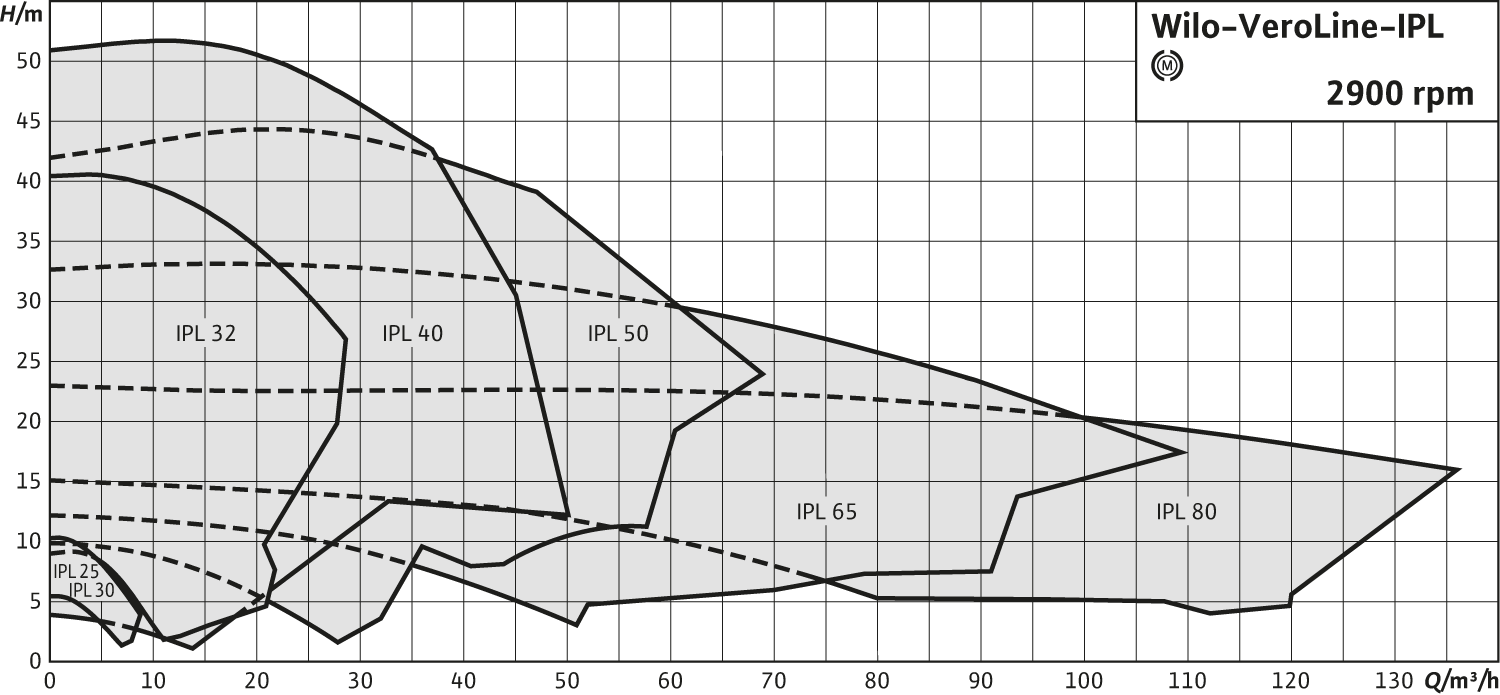

Replacement pump - Conventional Exchange sheet

Comment

Product information

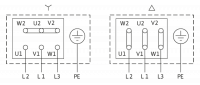

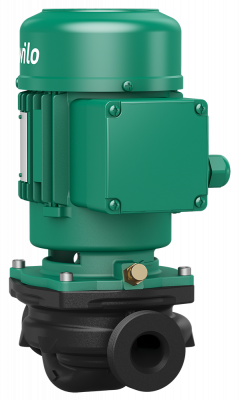

IPL 25/70-0,12/2

Your advantages

- High standard of corrosion protection thanks to cataphoretic coating

- Standard condensate drainage holes in the motor housings and lanterns

- Series design: motor with one-piece shaft

- Version N: Standard motor V1 with stainless steel plug shaft

- Bidirectional, force-flushed mechanical seal

Glanded pump in in-line design with screwed connection or flange connection.

Application

Pumping of heating water (acc. to VDI 2035), cold water and water/glycol mixtures without abrasive substances in heating, cold water and cooling systems.

Scope of delivery

- Pump

- Installation and operating instructions

- Permissible temperature range -20 °C to +120 °C

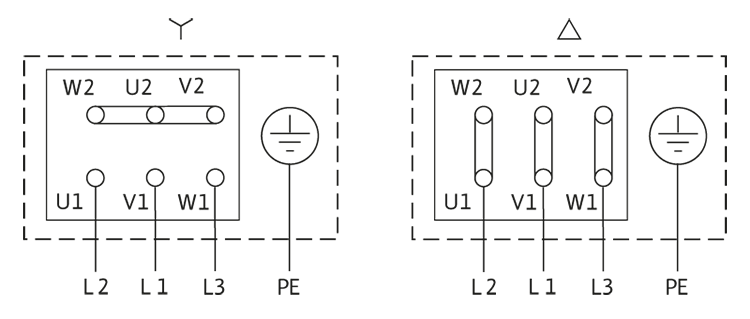

- Mains connection 3~400 V, 50 Hz (others on request)

- Protection class IP 55

- Nominal diameter Rp 1 to DN 100

- Max. operating pressure 10 bar (special version: 16 bar)

- Pump housing and lantern: EN-GJL-250

- Impeller: PPO fibreglass-reinforced EN-GJL-200 (depending on pump type)

- Shaft: 1.4021

- Mechanical seal: AQEGG; other mechanical seals on request

Single-stage, low-pressure centrifugal pump in in-line design with:

- Mechanical seal

- Flange connection with pressure measuring connection R 1/8

- Motor with one-piece shaft

Automatic reactivation of pump after power failure and automatic fault acknowledgement after cooling off of the motor.

Equipment/function:

- Full motor protection tripping unit for pumps with thermal winding contact (WSK)

- Switch on/off with integrated run signal light

- Terminals for external, potential-free activation/deactivation

- Connection terminal strip

Automatic reactivation of pump after power failure and automatic fault acknowledgement after cooling off of the motor.

Equipment/function:

- Full motor protection tripping unit for pumps with thermal winding contact (WSK)

- Switch on/off with integrated run signal light

- Fault signal light

- Terminals for external, potential-free activation/deactivation

- Potential-free contacts for external run signal (SBM) and fault signal (SSM)

- Connection terminal strip

- Switchgear SK 622N

- 4 threaded cable connections M20

- Installation and operating instructions