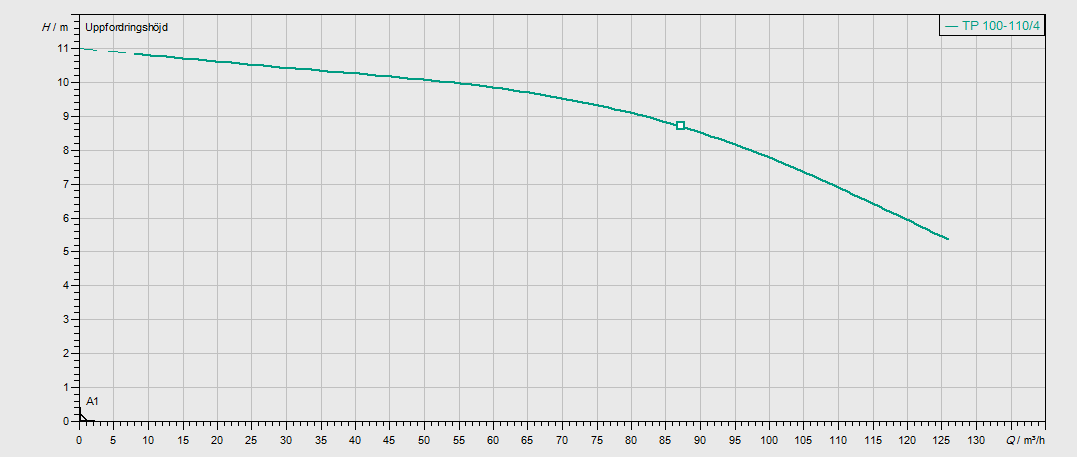

Existing pump - Circulation Pump curve

Replacement pump - High Efficiency Premium Smart Exchange sheet

Comment

Product information

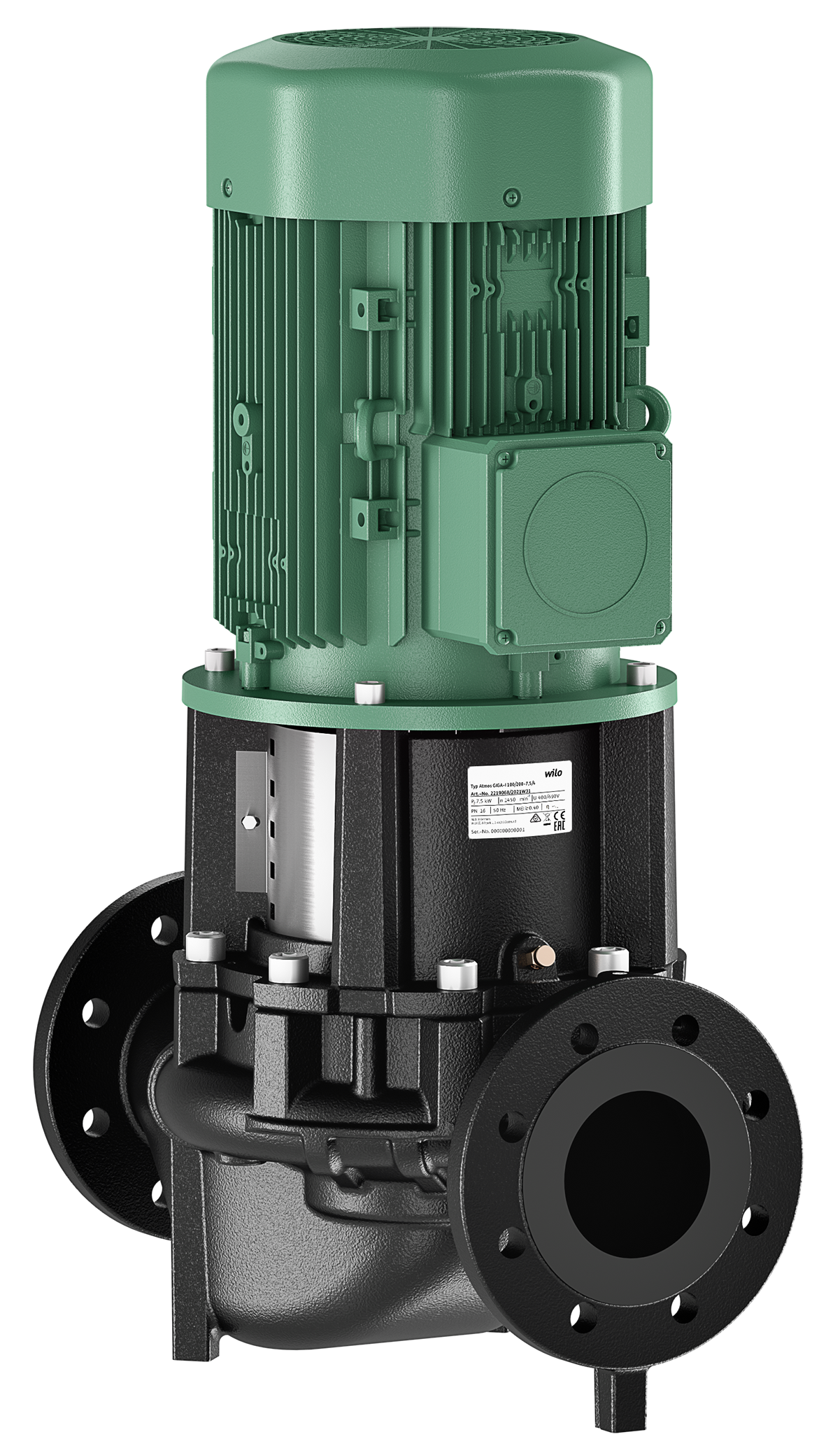

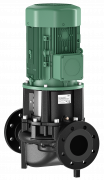

Stratos GIGA2.0-I 100/1-25/4,0

High-efficiency in-line pump with EC motor of energy efficiency class IE5 in accordance with IEC 60034-30-2, hydraulics with minimum efficiency index MEI ≥ 0.7 and electronic power adjustment in glanded pump construction. The pump is configured as a single-stage low-pressure centrifugal pump with flange connection and mechanical seal. The Stratos GIGA2.0-I has been predominantly designed for pumping heating water (acc. to VDI 2035), cold water and water-glycol mixtures without abrasive substances in heating, air-conditioning and cooling systems.

Design

- Single-stage low-pressure centrifugal pump with one-piece shaft in monobloc design

- Spiral housing in in-line design (suction and pressure ports with the same flanges in a line)

- PN 16 flange – drilled according to EN 1092-2

- Pressure measuring connections (R 1/8) for mounted differential pressure sensor (version ...-R1 without differential pressure sensor)

- Pump housing and motor flange with cataphoretic coating as standard

- Mechanical seal for pumping water up to Tmax. = +140 °C. A glycol admixture of 20 % to +40 % by volume is permitted up to T ≤ +40 °C. An alternative mechanical seal must be provided in water-glycol mixtures with glycol proportions > 40 % up to maximum 50 % by volume and a fluid temperature of > +40 °C up to maximum +120 °C or fluids other than water.

- Connection voltages: 3~440 V ±10 % 50/60 Hz; 3~400 V ±10 % 50/60 Hz; 3~380 V ±10 % 50/60 Hz

- Permanent, automatic performance adaptation to system requirements without setpoint specification Wilo Dynamic Adapt plus (factory setting).

- Constant temperature (T-const.)

- Constant differential temperature (dT-const.)

- Needs-based volume flow optimisation of the feeder pump through connectivity and communication between multiple secondary pumps (Multi-Flow Adaptation).

- Constant volume flow (Q-const.)

- Variable differential pressure (dp-v) with the option to set the nominal duty point Q and H

- Constant differential pressure (dp-c)

- Differential pressure control (dp-c) to a remote point in the pipe network (index circuit evaluator)

- Constant speed (n-const.)

- User-defined PID control

- Heat quantity measurement

- Cooling quantity measurement

- Adjustable volume flow limiter using the Q-Limit function (Qmin. and Qmax.)

- Operating modes of twin-head pump: Main/standby operation, efficiency-optimised parallel operation for dp-c and dp-v

- Pump automatically deactivates when no flow is detected (No-Flow Stop)

- Switchover between heating and cooling mode (automatic, external or manual)

- Ability to save and restore configured pump settings (3 restoration points)

- Fault and warning messages shown in plain text with advice on resolving the issue

- Integrated full motor protection

- Control mode currently set

- Current setpoint

- Current volume flow (only if a differential pressure sensor is connected)

- Current fluid temperature (only if temperature sensor is connected)

- Current power consumption

- Cumulative electric consumption

- 4 configurable analogue inputs: 0 – 10 V, 2–10 V, 0 – 20 mA, 4 – 20 mA and commercially available PT1000 (only on two analogue inputs); +24 V DC power supply

- 2 configurable digital inputs (Ext. OFF, Ext. Min, Ext. Max, heating/cooling, manual override (uncoupled from building automation), operation lock (key lock and remote operation configuration protection))

- 2 configurable signal relays for run signals and fault messages

- Slot for Wilo-CIF modules with interfaces for building automation (BA) (optional accessories: CIF modules Modbus RTU, BACnet MS/TP, LON, PLR, CAN)

- Wilo Net as a Wilo system bus for communication between Wilo products, e.g. Multi-Flow Adaptation; twin-head pump operation and Wilo-Smart Gateway

- Automatic emergency operation with definable pump speed for exceptional circumstances, e.g. bus communication or sensor value malfunction

- Rotatable, graphic colour display (4.3 inches) with one button manual operation level

- Bluetooth interface via Wilo-Smart Connect module BT

- Use the Wilo-Assistant app to read and set operating data and –among other things– set up a commissioning protocol through the Bluetooth interface

- Integrated dual pump management (twin-head pumps are prewired) when using 2 single pumps as twin-head pump unit (connection via Wilo Net)

- Cable break detection when using an analogue signal (in connection with 2 – 10 V or 4 – 20 mA)

- Time stamp for error/warnings and historical operating data

- Continuous operating data memory

- Standard condensate drainage holes in the motor housing (closed upon delivery)

- Air vent valve on the lantern

- Pump

- Wilo-Smart Connect module BT

- Threaded cable glands with sealing inserts

- Installation instructions (short summary) and declaration of conformity

- 3 mounting brackets with fixation material for installation on a base

- Blind flanges for twin-head pump housing

- Installation aid for mechanical seal (incl. mounting bolts)

- CIF module PLR

- CIF module LON

- CIF module BACnet MS/TP

- Modbus RTU CIF module

- CIF module CANopen

- CIF module Ethernet Multi-protocol (Modbus TCP, BACnet/IP)

- Differential pressure sensor DDG 2 – 10 V

- Temperature sensor PT1000 AA

- Sensor sleeves for the installation of temperature sensors in the pipe

- Made of steel.

- Counter flanges (weld) are delivered complete (in pairs) with bolt, nut and flange gasket.

- Thickness: 2 mm.

- Inner diameter: 115 mm.

- Outer diameter: 152 mm.

For all pumps and standard motors for measuring the direction of rotation, rotating field frequency and current operating status.

Direction of rotation checking device also for all conventional pumps with alternating or three-phase motor.

Industrial standard due to its sturdy and robust plastic casing, graphical display with scratch-resistant monitor screen.

One-button manual operation level for the Wilo high-efficiency and energy-saving pumps, additional 4 buttons for:

- IR-Monitor on/off

- Lighting on/off

- Information/help

- Electrical and hydraulic actual values

- Power supply and duty point of the pump

- Statistical values

- Service information

- Device settings.

- Self-test pump

- Self-test IR-Monitor

- Battery status check.

Replacement pump - Conventional Exchange sheet

Comment

Product information

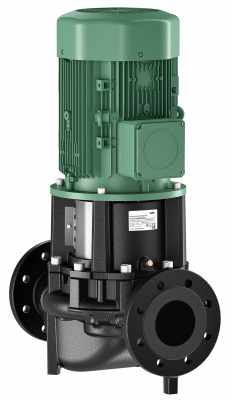

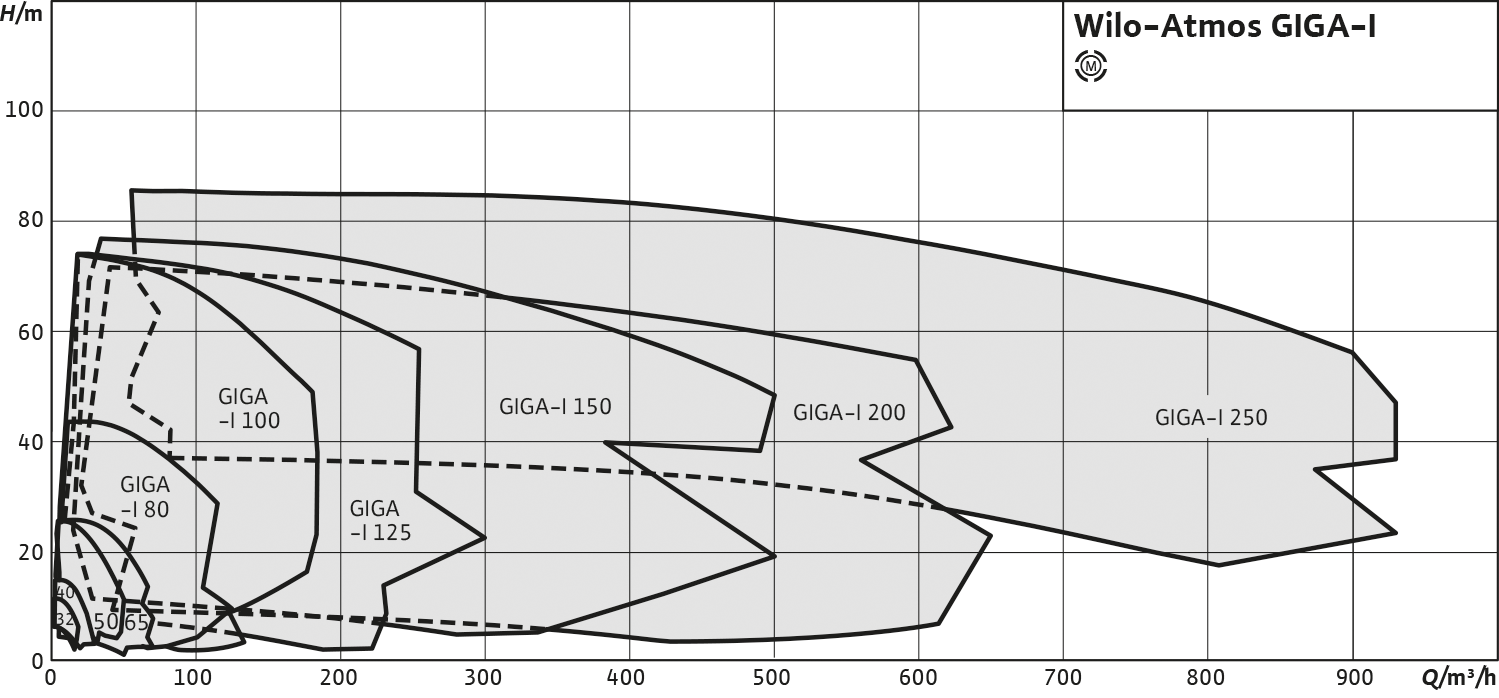

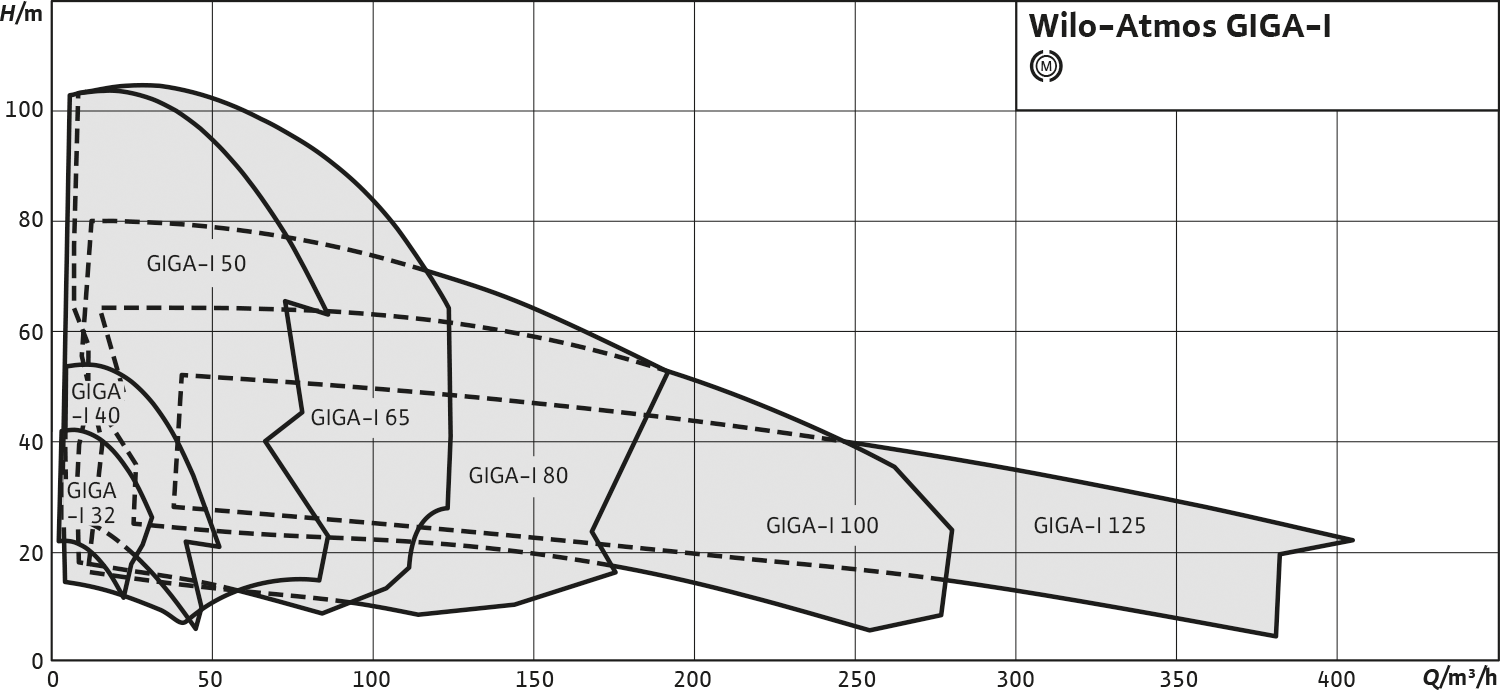

Atmos GIGA-I 100/160-3/4

Design

Glanded pump in in-line design with flange connection.

Application

The pumping of heating water (in accordance with VDI 2035), chilled water and water-glycol mixtures without abrasive substances in heating, chilled water and cooling systems.

Technical data

- Permitted temperature range of the fluid: -20 °C to +140 °C

- Max. ambient temperature 40 °C

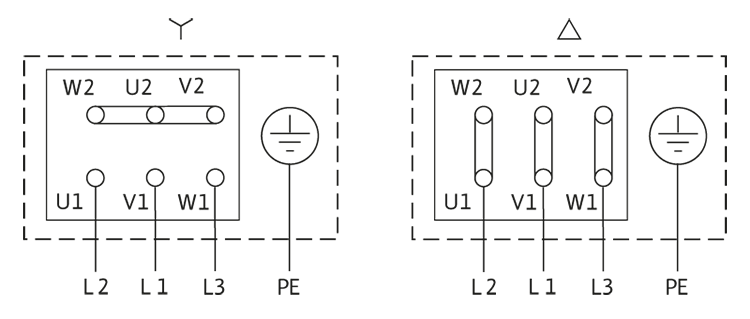

- Mains connection 3~400 V, 50 Hz (others on request)

- Protection class IP55

- Nominal diameter DN 32 to DN 250

- Standard version for operating pressure: 13 bar (up to +140 °C) / 16 bar (up to +120 °C)

- Pump housing and lantern: Standard: EN-GJL-250;

- Impeller: Standard: EN-GJL-200; special version: Bronze CuSn 10 stainless steel 1.4408

- Shaft: 1.4122

- Mechanical seal: AQEGG; other mechanical seals on request

Single-stage, low-pressure centrifugal pump in in-line design with:

- Mechanical seal

- Flange connection with pressure measuring connection R 1/8

- Lantern

- Coupling

- IEC standard motor

- Pump

- Installation and operating instructions

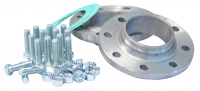

- Made of steel.

- Counter flanges (weld) are delivered complete (in pairs) with bolt, nut and flange gasket.

- Thickness: 2 mm.

- Inner diameter: 115 mm.

- Outer diameter: 152 mm.

Automatic reactivation of pump after power failure and automatic fault acknowledgement after cooling off of the motor.

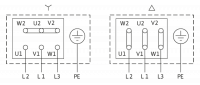

Equipment/function:

- Full motor protection tripping unit for pumps with thermal winding contact (WSK)

- Switch on/off with integrated run signal light

- Terminals for external, potential-free activation/deactivation

- Connection terminal strip

Automatic reactivation of pump after power failure and automatic fault acknowledgement after cooling off of the motor.

Equipment/function:

- Full motor protection tripping unit for pumps with thermal winding contact (WSK)

- Switch on/off with integrated run signal light

- Fault signal light

- Terminals for external, potential-free activation/deactivation

- Potential-free contacts for external run signal (SBM) and fault signal (SSM)

- Connection terminal strip

- Switchgear SK 622N

- 4 threaded cable connections M20

- Installation and operating instructions

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.