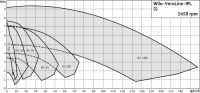

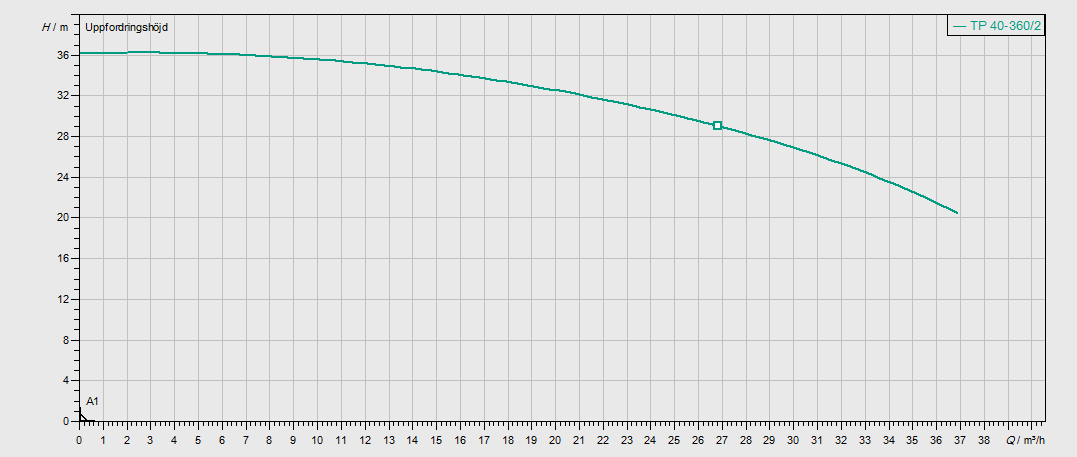

Existing pump - Circulation Pump curve

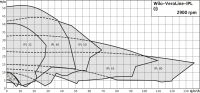

Replacement pump - High Efficiency Premium Exchange sheet

Exchange accessories

Comment

Product information

Stratos GIGA 40/1-45/3,8

Your advantages

- Innovative high-efficiency pump for maximum overall efficiency levels

- High-efficiency EC motor with efficiency class IE5 according to IEC 60034-30-2

- Highest possible operational reliability thanks to standby pump

- Optional interfaces for connection to building automation using insertable IF modules

The Wilo-Stratos GIGA is the ideal high-efficiency pump for use in heating, air conditioning and cooling applications in buildings where large volumes of water have to be pumped to great delivery heights. Wilo-Stratos GIGA offers ever greater operational reliability with the standby pump in the twin-head pump version.

Construction

High-efficiency in-line twin-head pump with EC motor and electronic power adjustment in glanded pump construction. Version as single-stage low-pressure centrifugal pump with flange connection and mechanical seal.

Application

The pumping of heating water (in accordance with VDI 2035), cold water and water-glycol mixtures without abrasive substances in heating, cold water and cooling systems.

Equipment/function

Operating modes

- Δp-c for constant differential pressure

- Δp-v for variable differential pressure

- PID-Control

- Constant speed (n=constant)

- Green button and display

- Differential pressure setpoint setting

- Setting the speed (manual control mode)

- Setting the operating mode

- Setting the pump ON/OFF

- Configuration of all operating parameters

- Fault acknowledgement

- "Overriding Off" control input

- “External pump cycling” control input (only effective in twin-head pump operation)

- Analogue input 0 – 10 V, 0 – 20 mA for constant speed (DDC) and remote setpoint adjustment

- Analogue input 2 – 10 V, 4 – 20 mA for constant speed (DDC) and remote setpoint adjustment

- Analogue input 0 – 10 V for actual value signal from pressure sensor

- Analogue input 2 – 10 V, 0 – 20 mA, 4 – 20 mA for actual value signal from pressure sensor

- Collective fault signal SSM

- Collective run signal SBM

- Infrared interface for wireless data exchange with IR-Monitor/IR-Stick

- Plug-in position for Wilo IF-Modules (Modbus, BACnet, CAN, PLR, LON) for connection to building automation

- Full motor protection with integrated trip electronics

- Access disable

- Main/standby operation (automatic fault-actuated switchover)

- Pump cycling main/standby operation after 24 hours

- Parallel operation

- Parallel operation (efficiency-optimised peak-load activation and deactivation)

- Pump

- Installation and operating instructions

- Technical data

- Permitted temperature range of the fluid: -20 °C to +140 °C

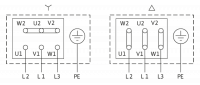

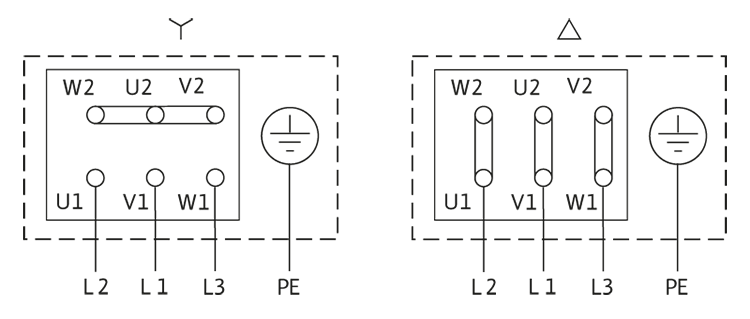

- Mains connection 3~480 V ±10 %, 50/60 Hz, 3~440 V ±10 %, 50/60 Hz, 3~400 V ±10 %, 50/60 Hz, 3~380 V -5 % +10 %, 50/60 Hz

- Protection class IP55

- Nominal diameter DN 40 to DN 100

- Max. operating pressure 16 bar

- Pump housing and lantern: EN-GJL-250

- Impeller: PPS-GF40 or EN-GJL-200 depending on the type

- Shaft: 1.4122

- Mechanical seal: AQEGG; other mechanical seals on request

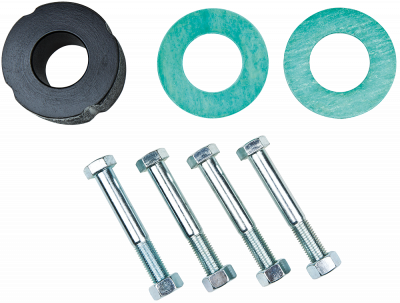

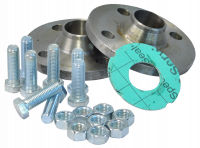

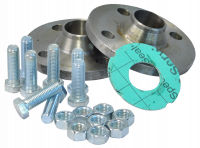

- Made of steel.

- Counter flanges (weld) are delivered complete (in pairs) with bolt, nut and flange gasket.

- Thickness: 2 mm.

- Inner diameter: 49 mm.

- Outer diameter: 85 mm.

For all pumps and standard motors for measuring the direction of rotation, rotating field frequency and current operating status.

Direction of rotation checking device also for all conventional pumps with alternating or three-phase motor.

Industrial standard due to its sturdy and robust plastic casing, graphical display with scratch-resistant monitor screen.

One-button manual operation level for the Wilo high-efficiency and energy-saving pumps, additional 4 buttons for:

- IR-Monitor on/off

- Lighting on/off

- Information/help

- Electrical and hydraulic actual values

- Power supply and duty point of the pump

- Statistical values

- Service information

- Device settings.

- Self-test pump

- Self-test IR-Monitor

- Battery status check.

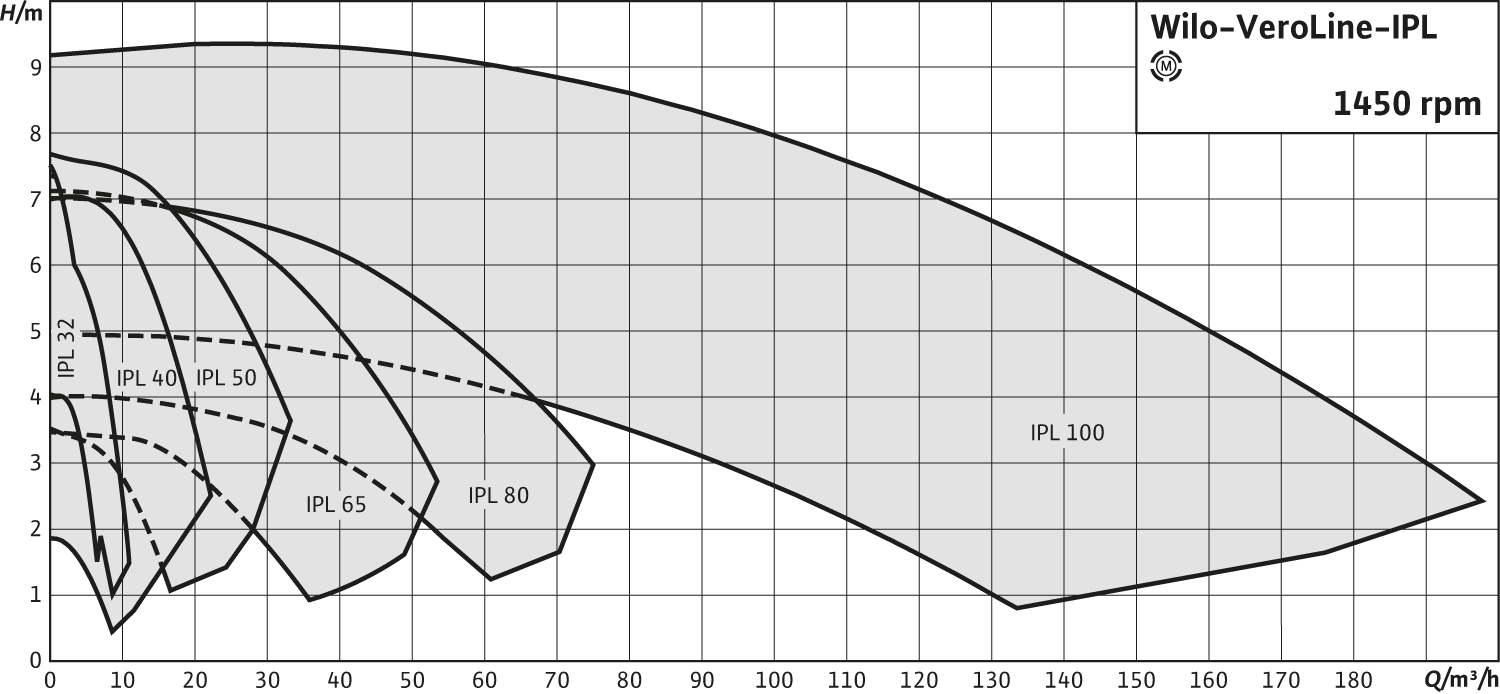

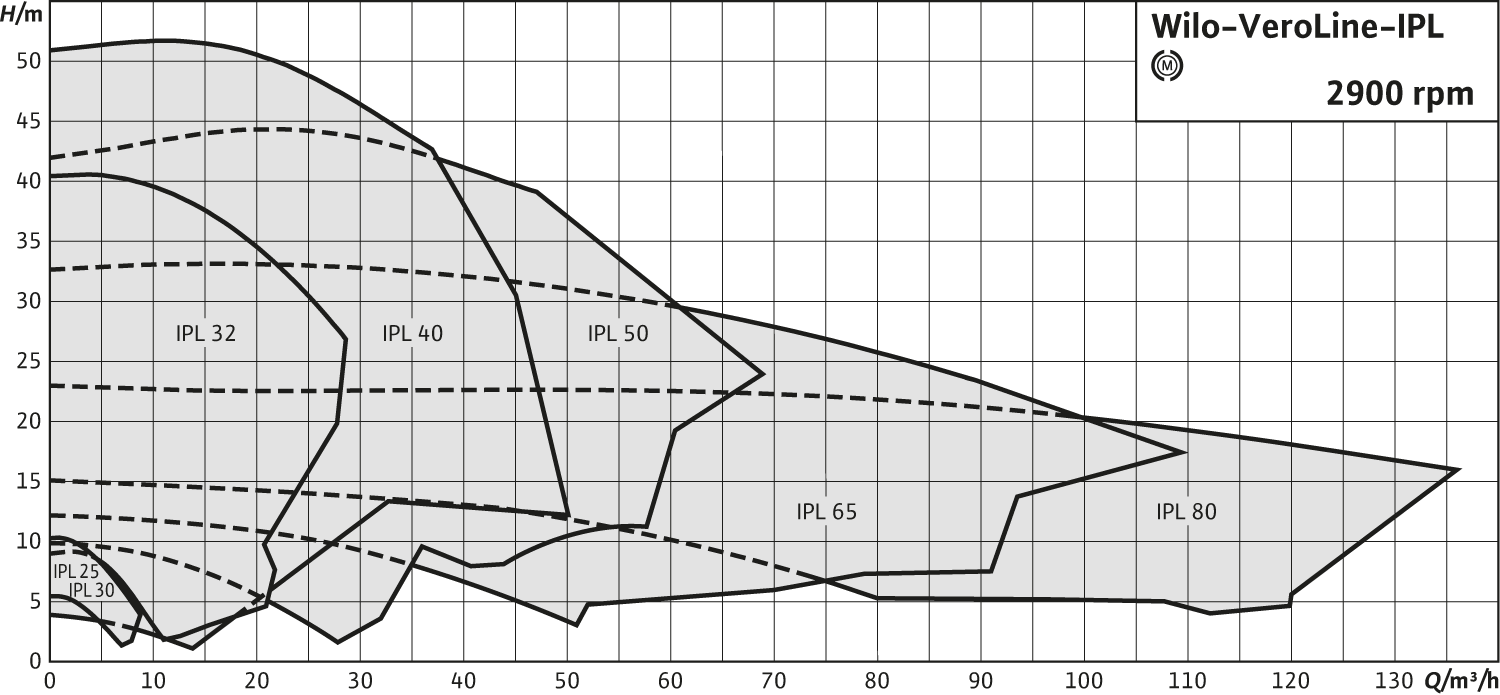

Replacement pump - Conventional Exchange sheet

Comment

Product information

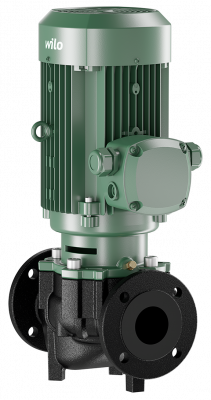

IPL 40/155-4/2

Your advantages

- High standard of corrosion protection thanks to cataphoretic coating

- Standard condensate drainage holes in the motor housings and lanterns

- Series design: motor with one-piece shaft

- Version N: Standard motor V1 with stainless steel plug shaft

- Bidirectional, force-flushed mechanical seal

Glanded pump in in-line design with screwed connection or flange connection.

Application

Pumping of heating water (acc. to VDI 2035), cold water and water/glycol mixtures without abrasive substances in heating, cold water and cooling systems.

Scope of delivery

- Pump

- Installation and operating instructions

- Permissible temperature range -20 °C to +140 °C

- Mains connection 3~400 V, 50 Hz (others on request)

- Protection class IP 55

- Nominal diameter Rp 1 to DN 100

- Max. operating pressure 10 bar (special version: 16 bar)

- Pump housing and lantern: EN-GJL-250

- Impeller: PPO fibreglass-reinforced EN-GJL-200 (depending on pump type)

- Shaft: 1.4021

- Mechanical seal: AQEGG; other mechanical seals on request

Single-stage, low-pressure centrifugal pump in in-line design with:

- Mechanical seal

- Flange connection with pressure measuring connection R 1/8

- Motor with one-piece shaft

- Made of steel.

- Counter flanges (weld) are delivered complete (in pairs) with bolt, nut and flange gasket.

- Thickness: 2 mm.

- Inner diameter: 49 mm.

- Outer diameter: 85 mm.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.