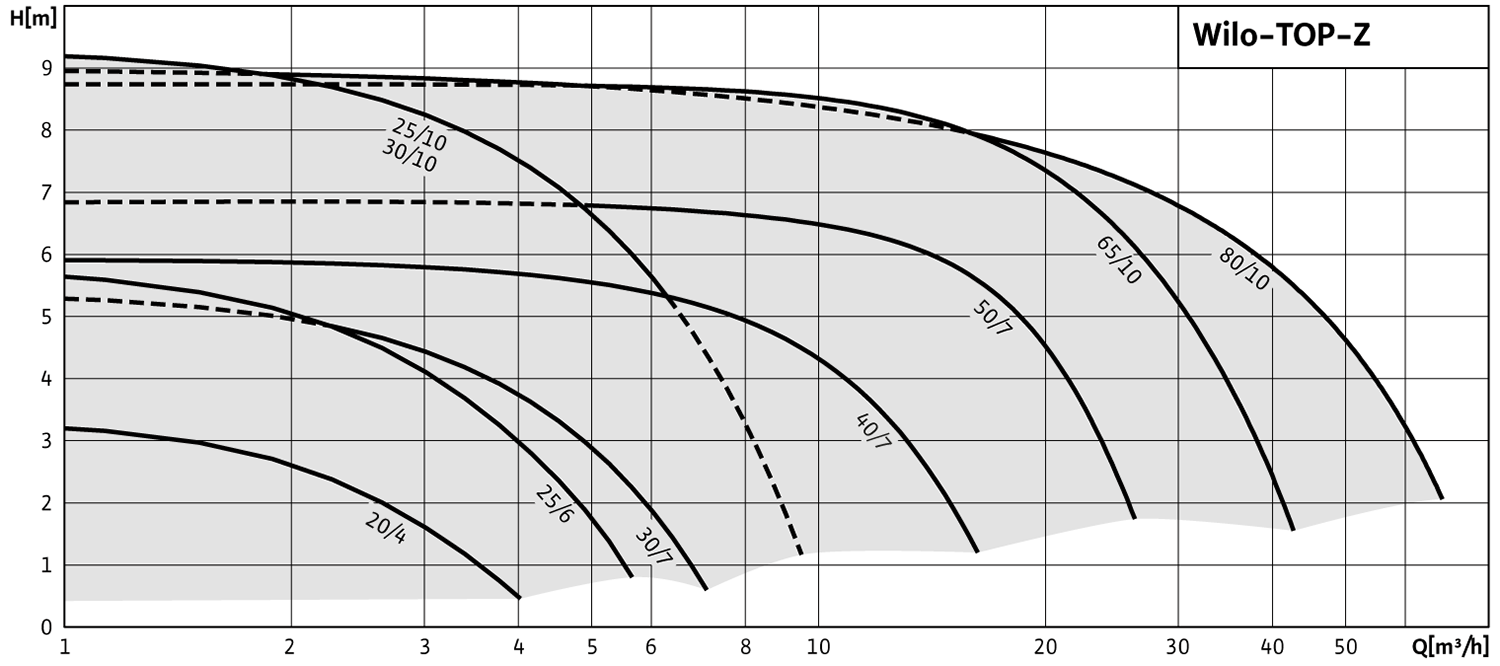

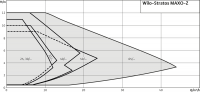

Existing pump - Circulation Pump curve

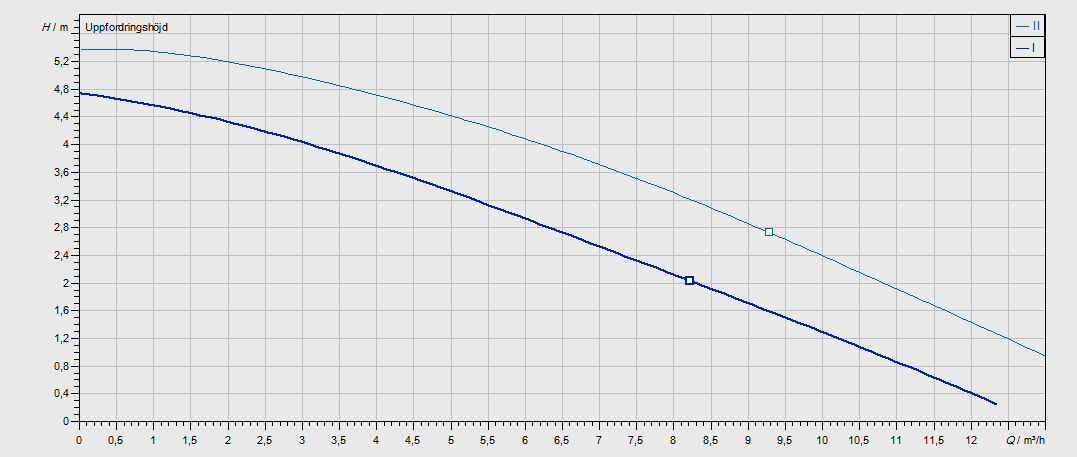

Replacement pump - High Efficiency Premium Smart Exchange sheet

Exchange accessories

Comment

Product information

Stratos MAXO-Z 40/0,5-8

Your advantages

- Intuitive operation by means of application-guided settings with the Setup Guide plus the combination of a new display and operating button using Green Button Technology.

- Highest standard of drinking water hygiene and energy efficiency with the new, innovative, intelligent T-const. control function.

- Optimum hygiene promotion through thermal disinfection detection.

- Latest communication interfaces (e.g. Bluetooth) for connection to mobile devices and direct pump networking for multiple pump control via Wilo Net.

- Maximum convenience in electrical installation thanks to a clearly arranged and spacious terminal room and the optimised Wilo-Connector.

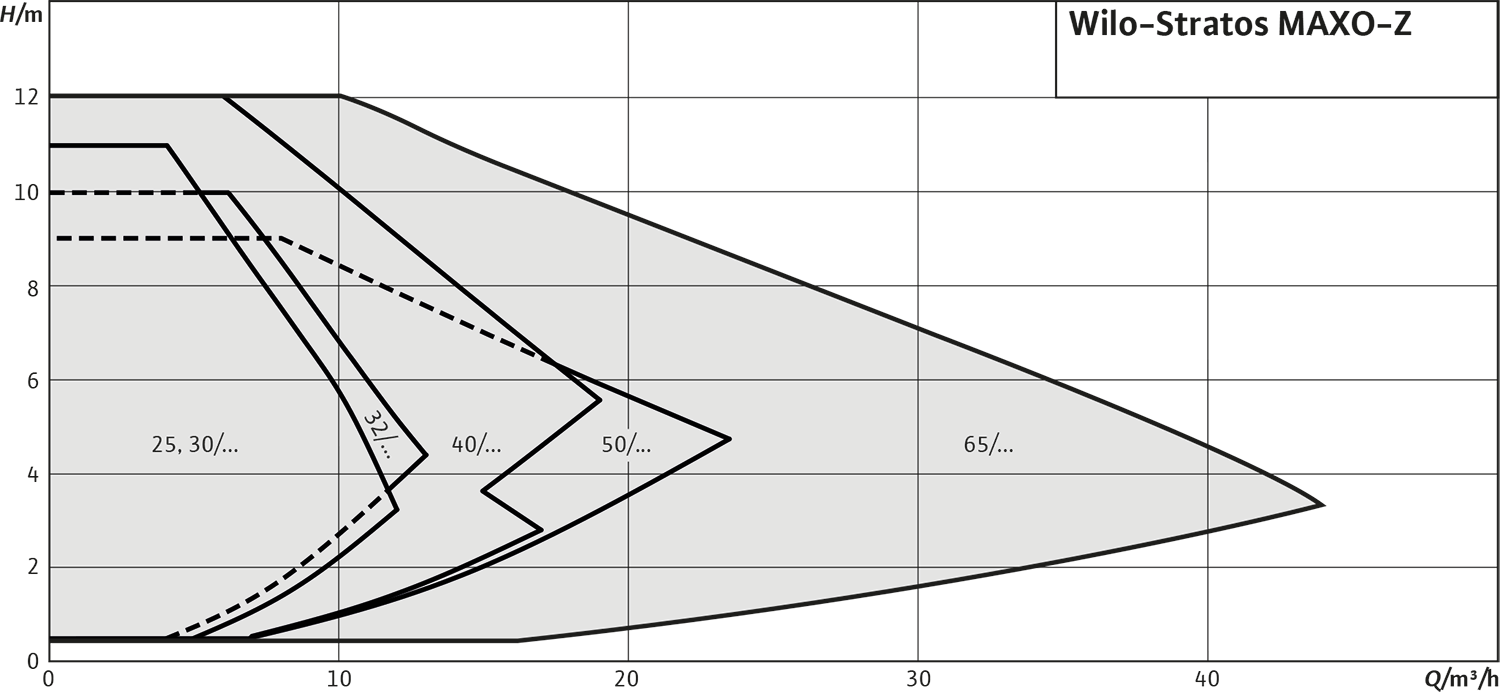

The Wilo-Stratos MAXO-Z has specifically been developed for drinking water applications and combines the innovative characteristics of the Wilo-Stratos MAXO with a stainless steel housing. The durable and hygienic material sets it apart from other domestic hot water circulators on the market.

Construction

Smart glandless circulator with screwed connection or flange connection, EC motor with integrated electronic power adjustment.

Application

Domestic hot water circulation systems of all kinds, hot-water heating systems of all kinds, air-conditioning, closed cooling circuits, industrial circulation systems.

Equipment/function

Field of application:

The pump facilitates an operation with highest system efficiency via precise setting of the control mode for the system-specific application (e.g. radiator, underfloor heating, ceiling cooling).

Heating

- Radiator

- Underfloor heating

- Ceiling heating

- Fan heater

- Hydraulic shunt

- Heat exchanger

- Ceiling cooling

- Underfloor cooling

- Air-conditioning devices

- Hydraulic shunt

- Heat exchanger

- Automatic switchover

Control modes

- Constant speed (control mode)

- Δp-c for constant differential pressure

- Δp-v for variable differential pressure

- Dynamic Adapt plus for continuous (dynamic) adjustment of the delivery rate to the current requirement

- T-const. for constant temperature regulation

- ΔT for differential temperature control

- Constant Q for constant volume flow control

- Multi-Flow Adaptation: Total volume flow determination through the feeder pump for the needs-based supply of secondary pumps in the heating circuit distributors

- User-defined PID controller

- Q-limitmax. for limiting the maximum volume flow

- Q-limitmin. for limiting the minimum volume flow

- No-Flow Stop (zero-flow-deactivation)

- Automatic setback operation

- Index circuit evaluator (Δp-c control with external actual value sensor)

- Thermal disinfection detection

- Variable pitch of Δp-v pump curve

- Selection of the field of application using the Setup Guide

- Setting the related operating parameters

- Nominal duty point: direct input of calculated duty point at Δp-v

- Status display

- Setting and resetting the energy meters (heating and cooling)

- Pump venting function

- Key lock for disabling the settings

- Function for resetting the factory settings or the saved restoration points (parameter sets)

- Parameterising the analogue inputs

- Parameterising the binary inputs

- Parameterising the relay outputs

- Power adjustment according to requirements for energy-efficient operation depending on the operating mode

- Setback operation

- Deactivation at zero flow (No-Flow Stop)

- Soft start

- Automatic troubleshooting routines (e.g. deblocking function)

- Switchover heating/cooling mode

- Full motor protection with integrated trip electronics

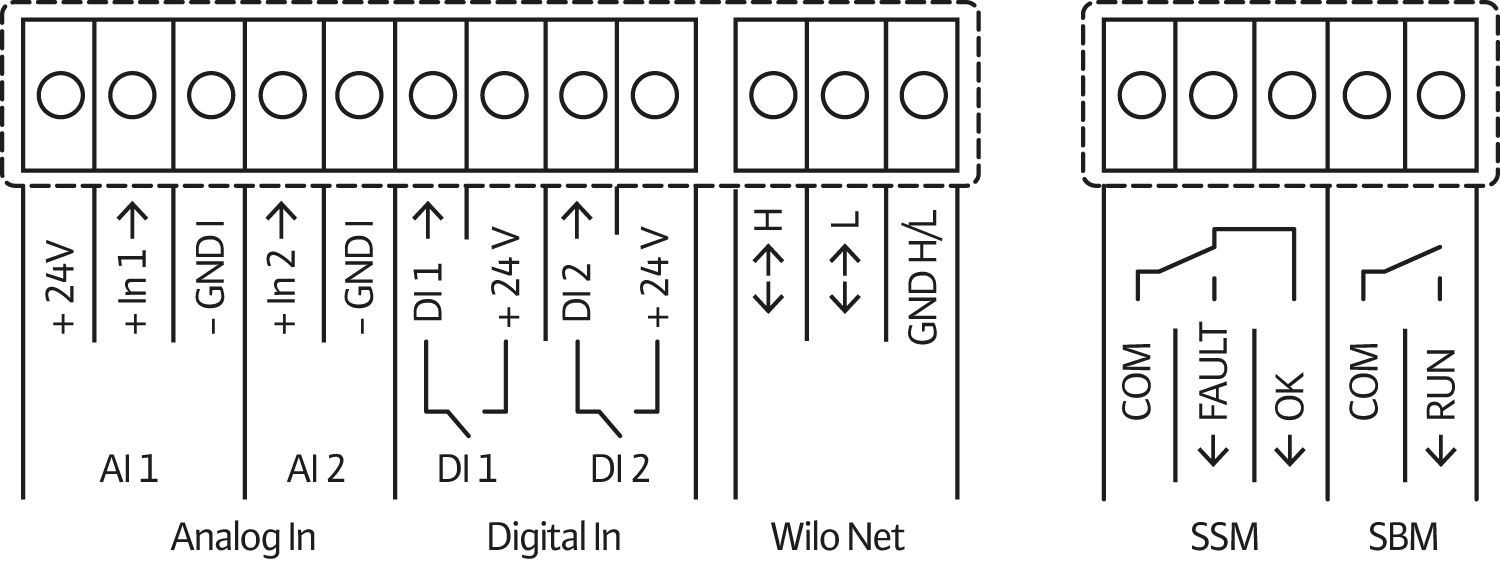

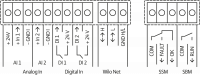

2 x analogue inputs:

- Signal types: 0 – 10 V, 2 – 10 V, 0 – 20 mA, 4 – 20 mA, PT1000

- Applications: Remote adjustment of the setpoints in every control mode (except Multi-Flow Adaptation), sensor inputs for temperature, differential pressure or free sensor in user-defined PID-operating mode

- For potential-free control outputs or switch

- Parametrizable functions:

- Ext. Off

- Ext. Min

- Ext. Max

- MANUAL (BMS-OFF)

- Key lock

- Switchover between heating/cooling mode

Signal and display functions

- Display status operation display:

- Setpoint

- Actual delivery head

- Actual volume flow

- Power consumption

- Electric consumption

- Temperatures

- Status display LED: Faultless operation (green LED), pump communication (blue LED)

- Display status of display fault (display red):

- Error codes and error description in full text

- Remedial measures

- Display status of display warning (display yellow):

- Warning codes and description of the warning in full text

- Remedial measures

- Display status process indicator display (display blue):

- Pump venting

- Update procedure

- Display BMS communication (display blue):

- Summary of the active BMS parameters (baud rate, address,...)

- Collective fault signal SSM (potential-free changeover contact)

- Collective run signal SBM (potential-free normally open contact)

- Bluetooth interface for wireless data exchange and remote operation of the pump using a smartphone or tablet.

- Serial digital interface Modbus RTU for connecting building automation (BA) via RS485 bus system (possible with Wilo-CIF module Modbus RTU).

- Serial digital interface BACnet MS/TP for connecting building automation (BA) via RS485 bus system (possible with Wilo-CIF module BACnet MS/TP).

- Serial digital interface LON for connecting building automation (BA) via bus system LONWorks (possible with Wilo-CIF module LON).

- Serial digital interface PLR for connecting BA via company-specific coupling module (possible with Wilo-CIF module PLR).

- For flange-end pumps: Flange versions

- Standard version for DN 32 to DN 65 pumps: PN 6/10 combination flange (PN 16 flange according to EN 1092-2) for PN 6 and PN 16 counter flanges

- Standard version for DN 80/DN 100 pumps: PN 6 flange (designed for PN 16 according to EN 1092-2) for PN 6 counter flange

- Special version for DN 32 to DN 100 pumps: PN 16 flange (according to EN 1092-2) for PN 16 counter flange

- Various integrated communication interfaces and optionally usable CIF module plug-in position

- 5 cable inlets for connecting the communication interfaces

- Bluetooth interface

- High resolution graphic display with green button and 2 additional buttons

- User-friendly terminal room

- Integrated temperature sensor

- Thermal insulation as standard for heating applications

- Quick electrical connection with optimised Wilo-Connector for the power supply

- Pump

- Optimised Wilo-Connector

- 2x threaded cable connection M16 x 1.5

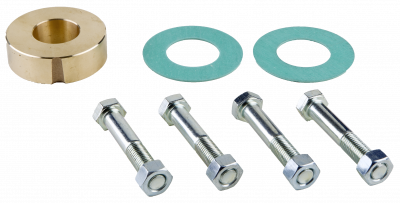

- Washers for flange screws (for nominal connection diameters DN 32 - DN 65)

- Including gaskets for threaded connection

- Thermal insulation

- Installation and operating instructions

- Permissible temperature range

- Drinking water up to 3.57 mmol/l (20 °dH): 0 °C to +80 °C

- Heating water: -10 °C to +110 °C

- Mains connection 1~230 V, 50/60 Hz

- Protection class IPX4D

- Screwed connection or flange connection (depending on type) Rp 1 to DN 65

- Max. operating pressure of standard version: 6/10 bar (special version: 16 bar)

- Insulation class: F

- Emitted interference in acc. with: EN 61800-3:2004+A1:2012 / residential environment (C1)

- Interference resistance in acc. with: EN 61800-3:2004+A1:2012 / industrial environment (C2)

- Pump housing made of stainless steel

- Thermal insulation: polypropylene

- Impeller: Plastic

- Shaft: Stainless steel

- Bearing: carbon

- Smart glandless circulator with EC motor and integrated electronic power adjustment

- Green Button Technology and graphic display

- Motor protection with trip electronics

- Plug connection for functional extension with optional CIF module for building automation (BA)

- Impeller with three-dimensionally curved blades and plastic sealing tube made of carbon fibre composite material

- Fits all Strato's MAXO pumps.

- Fits all Strato's MAXO pumps.

- Thickness: 2 mm.

- Inner diameter: 49 mm.

- Outer diameter: 85 mm.

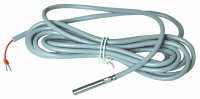

Connection to Stratos Maxo to detect the fluid temperature in the case of temperature-dependent pump control or to detect heating/cooling quantities.

- Sensor Pt 1000 Class AA, ø6 x 40 mm

- Cable length: 3 m

- Measurement range: -5 °C to 70 °C, briefly up to 90 °C

Connection to Stratos Maxo-Z to detect the hot water outlet temperature on the reservoir to detect the thermal disinfection.

- Sensor Pt 1000 Class B, ø8.5 x 35 mm

- Cable length 5 m

- Measurement range -5 °C to 70 °C, briefly up to 90 °C.

For admission of the immersion sensor Pt 1000 AA for connection to Stratos MAXO.

- Thread: G 1/2

- Inner Ø 6.4 mm for sensor to ø6 mm

- Length of engagement 100 mm for installation in thread T-connector for use with pipes from approx. DN 65 to DN 100

For admission of the immersion sensor Pt 1000 AA for connection to Stratos MAXO.

- Thread: G 1/2

- Inner Ø 6.4 mm for sensor to ø6 mm

- Length of engagement 45 mm for installation in thread T-connector for use with pipes from DN 25 to approx. DN 50

General functions

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions:

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions:

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

Enables remote monitoring and control of connected products using the Wilo-Smart connect function in the Wilo Assistant app.

General functions

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions:

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

Replacement pump - Conventional Exchange sheet

Comment

Product information

TOP-Z 40/7 1~

Your advantages

- Direction of rotation signal lamp for displaying the correct sense of rotation (only with 3~)

- With thermal insulation as standard

Glandless circulator with screwed connection or flange connection. Pre-selectable speed stages for power adjustment.

Application

Domestic hot water circulation systems in industry and building services.

Equipment/function

Operating modes:

- Speed-stage switching

- Setting the speed stages: 3 speed stages

- Internal protection against unacceptably high winding temperatures (only for pumps with P2 < 180 W, optional for all types with switchgears SK 602N and SK 622N).

- Thermal winding contact (WSK, potential-free NC contact) (only for pumps with P2 ≥ 180 W)

- Direction of rotation signal lamp (only for 3~ pumps)

- For flange-end pumps: Flange versions

- Standard version for DN 40 to DN 65 pumps: PN 6/10 combination flange (PN 16 flange according to EN 1092-2) for PN 6 and PN 16 counter flanges,

- Standard version for pumps DN 80: PN 6 flange (designed for PN 16 according to EN 1092-2) for PN 6 counter flange

- Special version for DN 40 to DN 80 pumps: PN 16 flange (according to EN 1092-2) for PN 16 counter flange,

- Cable inlet possible from both sides (only for 1~pumps and 3~pumps with P2≥180 W)

- Thermal insulation as standard

- Pump

- Including thermal insulation

- Including gaskets for threaded connection

- Including washers for flange screws (for nominal connection diameters DN 40 - DN 65)

- Including installation and operating instructions

- Permissible temperature range

- TOP-Z 20/4 and TOP-Z 25/6 drinking water up to 3.21 mmol/l (18 °dH): max. +65 °C, in short-term operation (2 h) up to +80 °C

- From TOP-Z 25/10 drinking water up to 3.57 mmol/l (20 °dH): max. +80 °C, in short-term operation (2 h) up to +110 °C

- Mains connection:

- 1~230 V, 50 Hz (depending on type)

- 3~230 V, 50 Hz (with optional switching plug)

- 3~400 V, 50 Hz

- Protection class IP X4D

- Screwed connection or flange connection (depending on type) Rp ¾ to DN 80

- Max. operating pressure of standard version: 6/10 bar or 6 bar (special version: 10 bar or 16 bar)

- Pump housing: Stainless steel/red brass/grey cast iron (depending on type)

- Impeller: Plastic

- Shaft: Stainless steel/ceramic (depending on type)

- Bearing: Carbon, synthetic resin impregnated

Automatic reactivation of pump after power failure and automatic fault acknowledgement after cooling off of the motor.

Equipment/function:

- Full motor protection tripping unit for pumps with thermal winding contact (WSK)

- Switch on/off with integrated run signal light

- Terminals for external, potential-free activation/deactivation

- Connection terminal strip