Existing pump - Drainage and sewage

Replacement pump Exchange sheet

Comment

Product information

Rexa UNI-V05A/T008-540/O

Your advantages

- Excellent reliability due to corrosion-free hydraulics for universal application and various fluids

- Easy installation thanks to its light weight, integrated capacitor at the single-phase motor and flange with integrated fixation

- Optimum efficiency and operational safety thanks to its vortex hydraulics and smooth surfaces

- Quick maintenance facilitated by direct access to the sealing chamber and pump housing

- Long maintenance interval thanks to its double seal and a high volume sealing chamber

Submersible sewage pump for intermittent operation for stationary and portable wet well installation.

Application

Pumping of:

- Sewage containing faeces in accordance with EN 12050-1

- Wastewater

- Fluids with a pH value of > 4.5

- Material version "B": Aggressive fluids, e.g. lake/sea water, condensate, distilled water

- Winding temperature monitoring with bimetallic strip

- Submersible sewage pump with 10 m cable

- Operating and maintenance manual

- Mains connection: 1~230 V, 50 Hz or 3~400 V, 50 Hz

- Submerged operating mode: S1

- Non-immersed operating mode: S2-15 min; S3 10%

- Protection class: IP68

- Insulation class: F

- Fluid temperature: 3 – 40 °C, max. 60 °C for 3 min

- Free passage: 44 mm

- Cable length: 10 m

- Motor housing: 1.4301

- Hydraulics housing: PP-GF30 (copolymer)

- Impeller: PP-GF30 (copolymer)

- Static gaskets: NBR

- Sealing on pump side: SiC/SiC

- Sealing on motor side: NBR (V05), C/MgSiO4 (V06)

- Shaft end: Stainless steel 1.4401

Description/construction

Submersible sewage pump as submersible monobloc unit for stationary and portable wet well installation.

Hydraulics

The outlet on the pressure side is designed as horizontal flange connection. The maximum possible dry matter is 8 %. Vortex impellers are used as the impeller shape. A pump support foot is integrated into the hydraulics housing.

Motor

The motors available are surface-cooled motors in single-phase version (with built-in operating capacitor) and three-phase version for the direct starting. The waste heat is given off directly to the surrounding fluid via the motor housing. These motors can operated immersed in continuous duty (S1) and non-immersed in short-time duty (S2) or intermittent periodic duty (S3).

Furthermore the motors are equipped with thermal motor monitoring. This protects the motor windings against overheating. For units with single-phase AC motors this is built-in and switches automatically. I.e. if the motor is switched off due to overheating and then cools down it is automatically switched on again. Bimetallic strips are used for this as standard.

The connection cable has a length of 10 m as standard and is available in following versions:

- With bare cable ends

- With plug

- With float switch and plug

There is a sealing chamber between the motor and hydraulics. This is filled with medicinal white oil. The seal on the fluid side is provided by a mechanical seal.

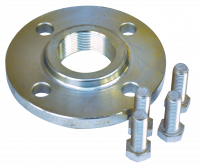

- Made of cast iron.

- Comes complete with flange, bolts and nuts, as well as gaskets.

- Maximum pump weight 400kg.

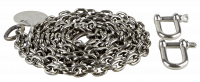

- Made of acid-resistant steel (1.4401).

- Length 5 meters.

- Intended for pumps in the Rexa series.

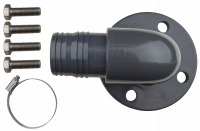

- Connection DN 50 / 2RK.

- Hose DN 50/60 (PVC).

- 90 degrees.

- Intended for pumps in the Rexa series.

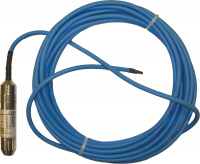

- Connection DN 50 PN10.

- Intended for pumps in the Rexa series.

- Connection DN 50 PN10.

Switching points: up ON / down OFF

Switching points: up ON / down OFF

Switching points: up ON / down OFF