Existing pump - Drainage and sewage

Replacement pump Exchange sheet

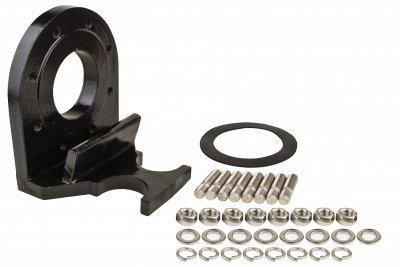

Exchange accessories

Comment

Product information

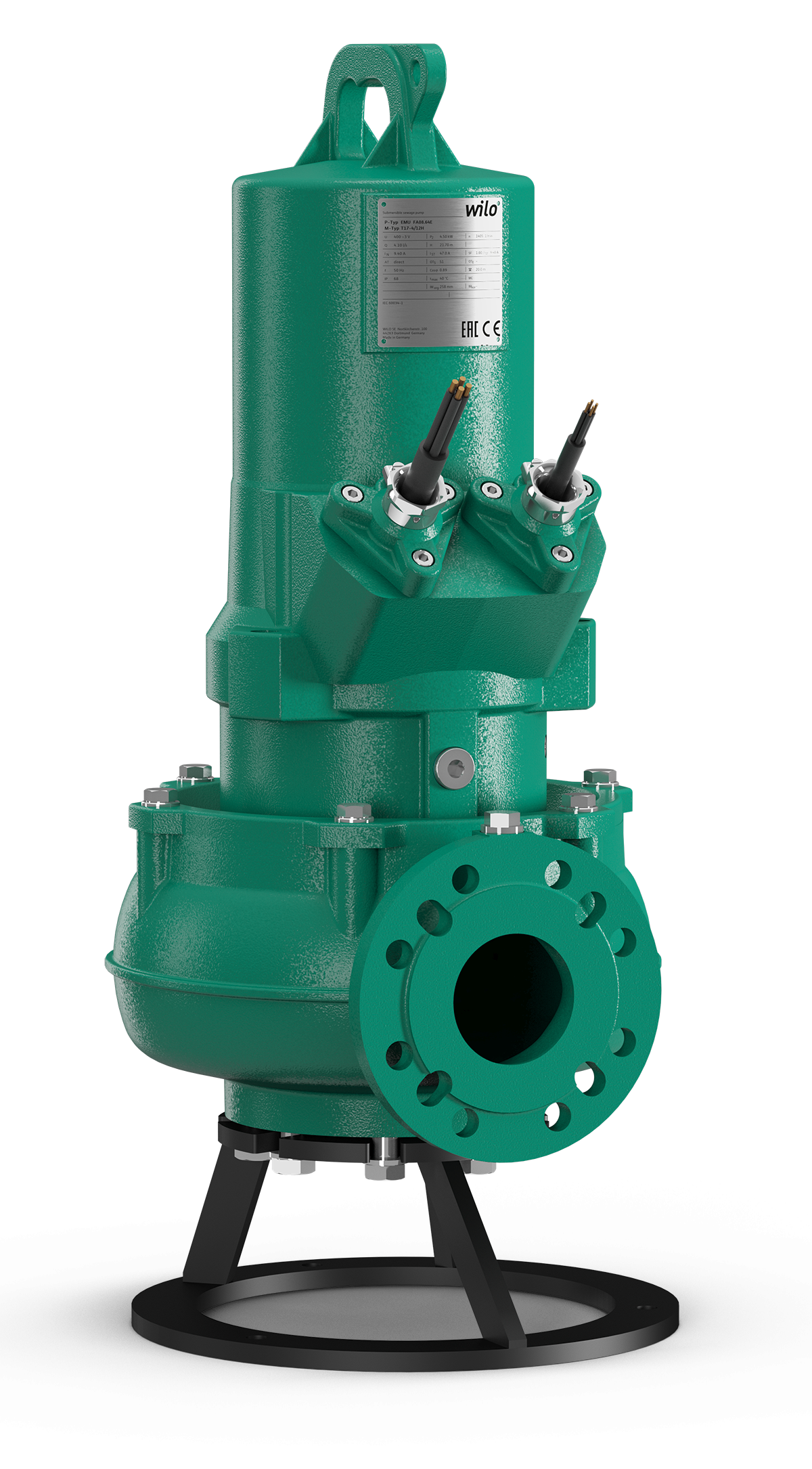

FA 10.82-245E + T 17.2-4/24HEx

Your advantages

- Operationally reliable and efficient thanks to single-channel hydraulics with large, free ball passage

- Process reliability thanks to optional monitoring for the sealing chamber

Submersible sewage pump without cooling system for continuous duty for stationary and portable wet well installation.

Application

Pumping of:

- Sewage containing faeces

- Pre-cleaned sewage without faeces and long-fibre components

- Wastewater

- Heavy-duty version made of grey cast iron

- Surface-cooled motor with Ex protection according to ATEX

- Winding temperature monitoring

- Submersible sewage pump ready for connection with 10 m connection cable without plug

- Installation and operating instructions

- Mains connection: 3~400 V, 50 Hz

- Submerged operating mode: S1

- Non-immersed operating mode: S2-15 or S2-30

- Protection class: IP68

- Insulation class: H

- Fluid temperature: 3…40 °C

- Cable length: 10 m

- Free ball passage from 45 mm to 100 mm

- Max. immersion depth: 20 m

- Pump housing: EN-GJL-250

- Impeller: EN-GJL or EN-GJS

- Static gaskets: NBR

- Fluid-side seal: Mechanical seal made of SiC/SiC

- Motor-side seal (depending on type): -Rotary shaft seal made of NBR - Mechanical seal made of SiC/SiC or carbon/ceramic

- Motor housing: EN-GJL-250

- Shaft: Stainless steel 1.4021

Submersible sewage pump as submersible monobloc unit for stationary and portable wet well installation.

Hydraulics

The outlet on the pressure side is designed as horizontal flange connection. The maximum possible dry matter content is 8 %, depending on the hydraulics and impeller type. The following impeller shapes are currently used:

- Vortex impeller (W)

- Single-channel impeller (E)

Motor

Surface-cooled motors (T motor) do not have a cooling system of their own and emit their heat directly to the surrounding fluid via the housing parts. The motors can therefore be used in immersed state for continuous duty. Depending on their size, they can also be used in non-immersed state for short-time duty.

All motors have a sealing chamber that protects the motor from fluid ingress. It can be accessed from the outside and can optionally be monitored with a rod electrode. All filling fluids used are potentially biodegradable and environmentally safe.

The cable inlet is longitudinally watertight, the cable length is 10 m and the cable has free ends.

Seal

Fluid-side and motor-side sealing is possible in the following versions depending on the motor type:

- Version H: Mechanical seal for the fluid side, rotary shaft seal for the motor side

- Version G: Two independently-acting mechanical seals

Ex rating

The motors have ex-approvals according to the ATEX directive.