Existing pump - Multistage

Replacement pump Exchange sheet

Comment

Product information

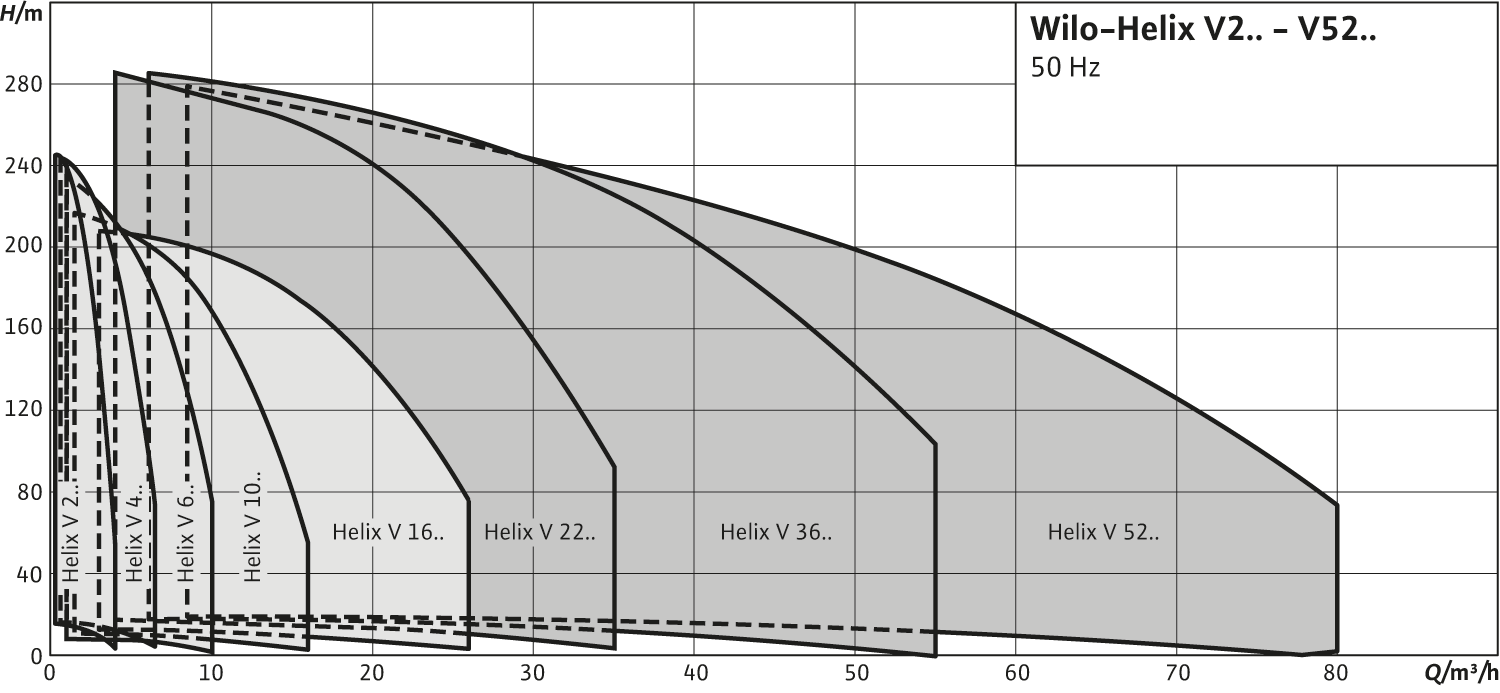

Helix V 406-1/16/E/KS/400-50

Your advantages

- Efficiency-optimised, laser-welded 2D/3D hydraulics, flow and degassing optimised

- Corrosion-resistant impellers, guide vanes and stage housings

- Flow and NPSH-optimised pump housing

- Maintenance-friendly design with particularly robust coupling guard

- Drinking water approval for pumps with parts that come in contact with the fluid made of stainless steel (EPDM version)

Non-self-priming, high-efficiency multistage high-pressure centrifugal pump in vertical design with in-line connections.

Application

- Water supply and pressure boosting

- Industrial circulation systems

- Process water

- Closed cooling circuits

- Fire extinguishing systems

- Washing systems

- Irrigation

- Corrosion-resistant impellers, guide vanes and stage housings

- Helix V high-pressure multistage centrifugal pump

- Installation and operating instructions

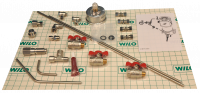

- Helix V 2 – 16 (version PN16 with oval flanges): counter flanges made of stainless steel with the corresponding screws, nuts and gaskets

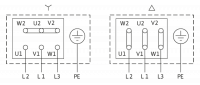

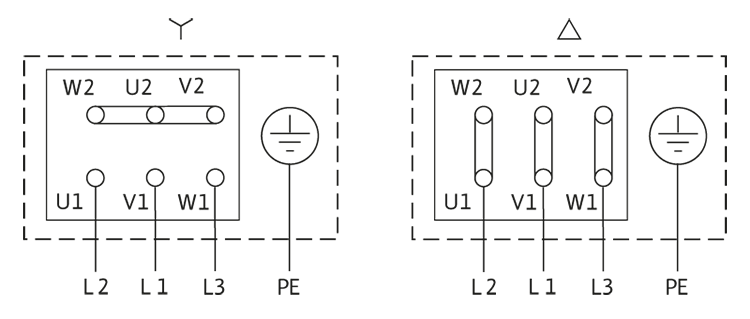

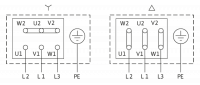

- Electrical connection:

- 3~400 V (±10 %), 50 Hz

- ≤ 4 kW 230 V/ 400 V; Δ/Y

- > 4 kW 400 V/ 690 V; Δ/Y

- 1~ 230 V (±10 %), 50 Hz, only Wilo-Helix V 2, 4, 6, 10

- Fluid temperature range:

- Helix V 2 – 16 (EPDM): -30 to 120 °C (130 °C on request)

- Helix V 2 – 16 for aggressive media (FKM): -15 to 90 °C

- Helix V22 – 52 (EPDM): -20 to 120 °C (130 °C on request)

- Helix V22 – 52 for aggressive media (FKM): -15 to 90 °C

- Max. operating pressure: 16/25/30 bar

- Max. inlet pressure of 10 bar

- Protection class: IP 55

- Max. ambient temperature: -15 °C – +50 °C (extended temperature ranges on request)

- Available versions:

- Helix V 2 – 16: PN 16 with oval flanges, PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005 (Victaulic coupling on request)

- Helix V 22 – 52: PN 16/PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005

Helix V 2, 4, 6, 10, 16:

Standard version

- Impellers, stage housings and guide vanes made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4301 (AISI 304)

- Baseplate and lantern in EN-GJL-250 (cataphoretic coated)

- Shaft made of stainless steel 1.4301 (AISI 304) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Impellers, stage housings and guide vane apparatuses of stainless steel 1.4404 (AISI 316L)

- Pump housing made of stainless steel 1.4404 (AISI 316L)

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of FKM (EPDM gasket on request)

- Jacket pipe made of stainless steel 1.4404 (AISI 316L)

Standard version

- Stage housings, impellers, guide vane apparatuses made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4308 (AISI 304) or cataphoretic-coated grey cast iron EN-GJL 250, loose flanges made of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

- Shaft made of stainless steel 1.4057 (AISI 431)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Stage housings, impellers, and guide vane apparatuses made of stainless steel 1.4404 (AISI 316L)

- Pump housing: all parts which come in contact with the media are made of cast stainless steel 1.4409 (AISI 316L); loose flanges of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

- Baseplate made of stainless steel 1.4301 (AISI 304)

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of FKM (EPDM gasket on request)

- Pressure shroud made of stainless steel 1.4404 (AISI 316L)

Description/construction

- Pumps can be adapted to specific circumstances on request (e.g. motor protection, IE4 motor efficiency class, VdS certified Wilo-Helix pumps, ATEX, extended ambient temperature range).

- The Helix series is also available with an integrated frequency converter.

Bypass kit for continuous ventilation of Helix pumps in series 2/ 4 / 6 / 10 / 16.

- Comes with pressure gauge.

- Suitable to use for all types of self and normal suction systems, e.g. irrigation, cooling towers etc.

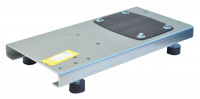

Foot plate is for mounting on foundation or floor. It fits all pumps in the Helix series with a maximum engine power of 5.5 kW.

- Pump housing (pump) is screwed into the foot plate with four bolts (dimension M8 or M10, depending on the pump size - see pump catalogue leaf), recommended length of bolt 40-70 mm.

- The foot plate is equipped with vibration dampers, one in each corner.

- Made of stainless steel.

- Dimensions: 405 x 90 x 405 mm (W x H x D).

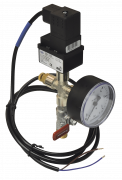

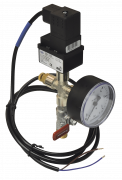

The safety valve protects the system against overpressure when using water supply and pressure relief systems.

- Activation pressure 10% above the factory preset pressure.

- Allowed media - water without abrasive particles.

- Media temperature max 130 ° C.

- House made of plaster / brass.

- Seal made by Perbunan / EPDM.

The safety valve protects the system against overpressure when using water supply and pressure relief systems.

- Activation pressure 10% above the factory preset pressure.

- Allowed media - water without abrasive particles.

- Media temperature max 130 ° C.

- House made of plaster / brass.

- Seal made by Perbunan / EPDM.

Connection to the joint tubing Rp ¼' threaded bushing.

The pressure switch locks at 1.0 bar and enables at 1.3 bar (factory works setting in accordance with DIN 1988).

The factory settings cannot be modified.

Replacement pump Exchange sheet

Comment

Product information

Helix V 406-1/16/E/S/400-50

Your advantages

- Efficiency-optimised, laser-welded 2D/3D hydraulics, flow and degassing optimised

- Corrosion-resistant impellers, guide vanes and stage housings

- Flow and NPSH-optimised pump housing

- Maintenance-friendly design with particularly robust coupling guard

- Drinking water approval for pumps with parts that come in contact with the fluid made of stainless steel (EPDM version)

Non-self-priming, high-efficiency multistage high-pressure centrifugal pump in vertical design with in-line connections.

Application

- Water supply and pressure boosting

- Industrial circulation systems

- Process water

- Closed cooling circuits

- Fire extinguishing systems

- Washing systems

- Irrigation

- Corrosion-resistant impellers, guide vanes and stage housings

- Helix V high-pressure multistage centrifugal pump

- Installation and operating instructions

- Helix V 2 – 16 (version PN16 with oval flanges): counter flanges made of stainless steel with the corresponding screws, nuts and gaskets

- Electrical connection:

- 3~400 V (±10 %), 50 Hz

- ≤ 4 kW 230 V/ 400 V; Δ/Y

- > 4 kW 400 V/ 690 V; Δ/Y

- 1~ 230 V (±10 %), 50 Hz, only Wilo-Helix V 2, 4, 6, 10

- Fluid temperature range:

- Helix V 2 – 16 (EPDM): -30 to 120 °C (130 °C on request)

- Helix V 2 – 16 for aggressive media (FKM): -15 to 90 °C

- Helix V22 – 52 (EPDM): -20 to 120 °C (130 °C on request)

- Helix V22 – 52 for aggressive media (FKM): -15 to 90 °C

- Max. operating pressure: 16/25/30 bar

- Max. inlet pressure of 10 bar

- Protection class: IP 55

- Max. ambient temperature: -15 °C – +50 °C (extended temperature ranges on request)

- Available versions:

- Helix V 2 – 16: PN 16 with oval flanges, PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005 (Victaulic coupling on request)

- Helix V 22 – 52: PN 16/PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005

Helix V 2, 4, 6, 10, 16:

Standard version

- Impellers, stage housings and guide vanes made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4301 (AISI 304)

- Baseplate and lantern in EN-GJL-250 (cataphoretic coated)

- Shaft made of stainless steel 1.4301 (AISI 304) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Impellers, stage housings and guide vane apparatuses of stainless steel 1.4404 (AISI 316L)

- Pump housing made of stainless steel 1.4404 (AISI 316L)

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of FKM (EPDM gasket on request)

- Jacket pipe made of stainless steel 1.4404 (AISI 316L)

Standard version

- Stage housings, impellers, guide vane apparatuses made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4308 (AISI 304) or cataphoretic-coated grey cast iron EN-GJL 250, loose flanges made of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

- Shaft made of stainless steel 1.4057 (AISI 431)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Stage housings, impellers, and guide vane apparatuses made of stainless steel 1.4404 (AISI 316L)

- Pump housing: all parts which come in contact with the media are made of cast stainless steel 1.4409 (AISI 316L); loose flanges of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

- Baseplate made of stainless steel 1.4301 (AISI 304)

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of FKM (EPDM gasket on request)

- Pressure shroud made of stainless steel 1.4404 (AISI 316L)

Description/construction

- Pumps can be adapted to specific circumstances on request (e.g. motor protection, IE4 motor efficiency class, VdS certified Wilo-Helix pumps, ATEX, extended ambient temperature range).

- The Helix series is also available with an integrated frequency converter.

Bypass kit for continuous ventilation of Helix pumps in series 2/ 4 / 6 / 10 / 16.

- Comes with pressure gauge.

- Suitable to use for all types of self and normal suction systems, e.g. irrigation, cooling towers etc.

Foot plate is for mounting on foundation or floor. It fits all pumps in the Helix series with a maximum engine power of 5.5 kW.

- Pump housing (pump) is screwed into the foot plate with four bolts (dimension M8 or M10, depending on the pump size - see pump catalogue leaf), recommended length of bolt 40-70 mm.

- The foot plate is equipped with vibration dampers, one in each corner.

- Made of stainless steel.

- Dimensions: 405 x 90 x 405 mm (W x H x D).

The safety valve protects the system against overpressure when using water supply and pressure relief systems.

- Activation pressure 10% above the factory preset pressure.

- Allowed media - water without abrasive particles.

- Media temperature max 130 ° C.

- House made of plaster / brass.

- Seal made by Perbunan / EPDM.

The safety valve protects the system against overpressure when using water supply and pressure relief systems.

- Activation pressure 10% above the factory preset pressure.

- Allowed media - water without abrasive particles.

- Media temperature max 130 ° C.

- House made of plaster / brass.

- Seal made by Perbunan / EPDM.

Connection to the joint tubing Rp ¼' threaded bushing.

The pressure switch locks at 1.0 bar and enables at 1.3 bar (factory works setting in accordance with DIN 1988).

The factory settings cannot be modified.