Existing pump - Multistage

Replacement pump Exchange sheet

Comment

Product information

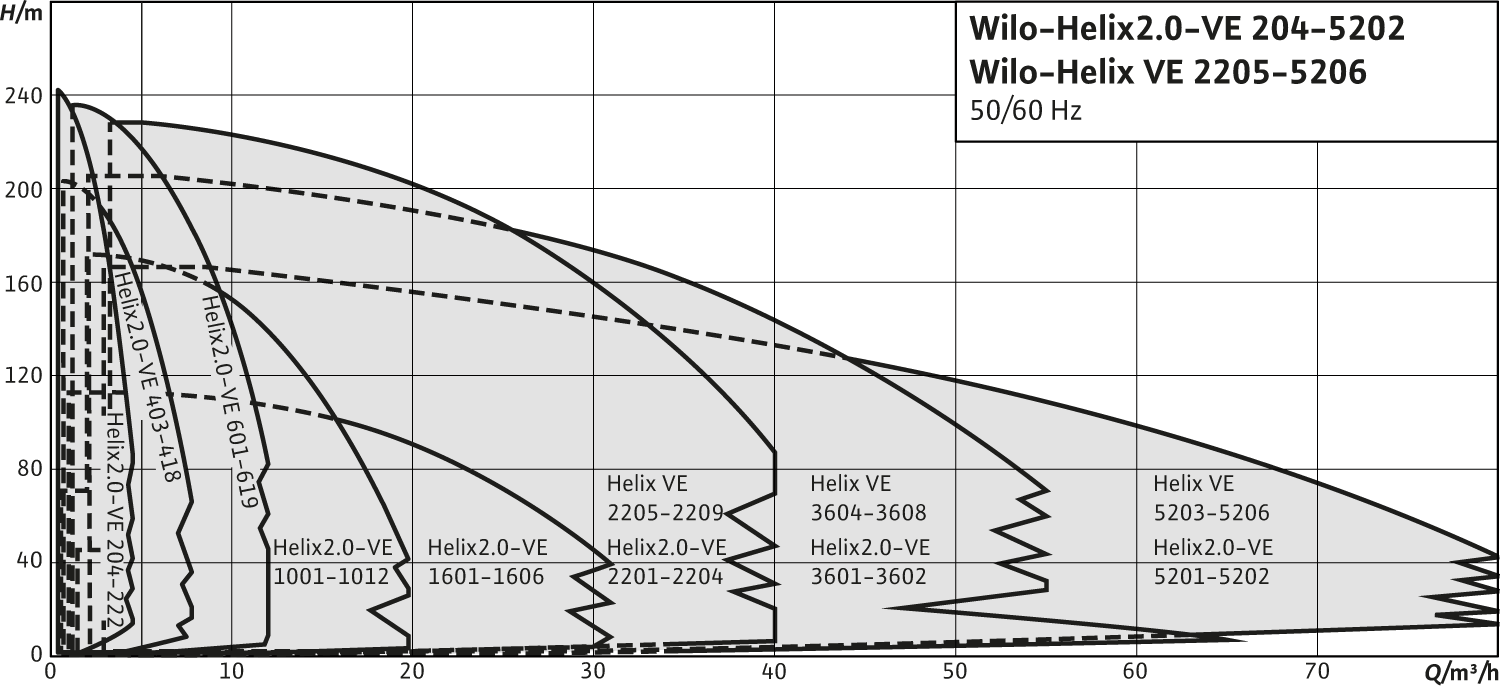

Helix2.0-VE 1601-1/16/E/KS/3

Design

Highly efficient, non-self-priming high-pressure multistage centrifugal pump in vertical design with in-line connections, equipped with electronically controlled EC motor of energy efficiency class IE5 in accordance with IEC 60034-30-2.

Application

- Water supply and pressure boosting

- Industrial circulation systems

- Process water

- Closed cooling circuits

- Heating

- Washing systems

- Irrigation

- 2” colored LCD display

- Wilo Green Button Technology and soft button with return function for menu navigation and pump setting

- Green LED indicates pump status

- Blue LED indicates that pump is influenced externally via an interface

- Impellers, guide vanes and stage housings made of corrosion-resistant material

- Constant pressure p-c

- Constant differential pressure ∆p-c

- Variable differential pressure ∆p-v

- Constant speed n-c

- PID control

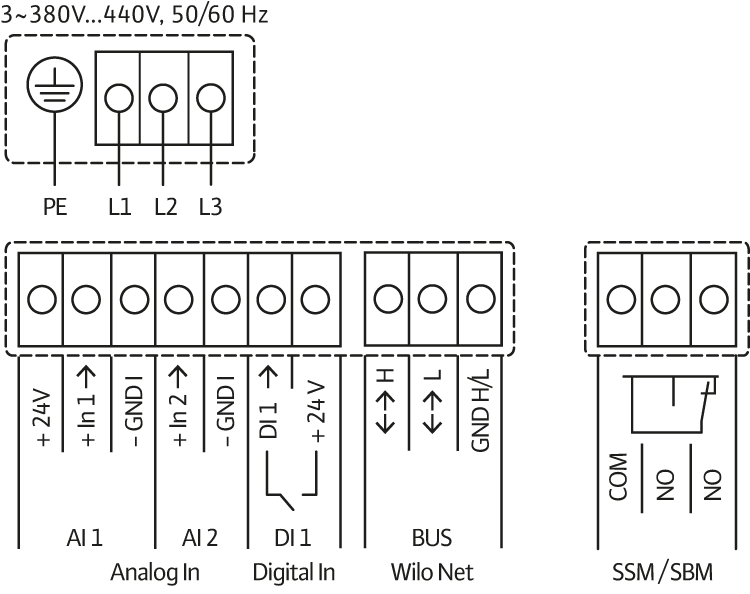

- IN (AI 1): Input sensor signal 4-20 mA, 0-10 V, 0-20 mA or 2-10 V

- IN (AI 2): Input setpoint 0-20 mA, 0-10 V, 4-20 mA, 2-10 V or input sensor signal 4-20 mA, 0-10 V, 0-20 mA or 2-10 V

- Extern off

- Lack of water detection by binary input

- Max. pressure limit detection

- Min. pressure limit detection

- Lack of water detection by suction sensor

- Zero flow test (open loop)

- No-Flow Stop (closed loop)

- Dry running detection

- Volume flow calculation by using differential pressure sensor

- Pump kick

- Error and warning codes

- Overload protection

- Access lock

- Plug-in position for Wilo CIF-modules PLR, LON, BACnet MS/TP, Modbus RTU, CANopen, Ethernet Multi-protocol (Modbus TCP, BACnet/IP) for connection to the building automation

- Main/standby operation

- Pump cycling main/standby operation after 24 hours or automatic fault-actuated switchover

- Wired connection via Wilo Net

Electrical connection:

- 3~ 380 V …440 V (+/- 10%) 50 Hz/60 Hz

- TN, TT, IT

- Helix2.0-VE 2 – 16 (EPDM): -30 to 120 °C (130 °C on request)

- Helix2.0-VE 2 – 16 for aggressive media (FKM): -15 to 90 °C

- Helix2.0-VE – 52 (EPDM): -20 to 120 °C (130 °C on request)

- Helix2.0-VE 22 – 52 for aggressive media (FKM): -15 to 90 °C (-30 to 120 °C with EPDM gasket on request)

Protection class: IP 55

Max. ambient temperature: +50°C

Available versions:

Helix2.0-VE 2 – 16: PN 16 with oval flanges, PN 25 with round flanges according to ISO 2531 and ISO 7005 (Victaulic coupling on request)

Helix2.0-VE 22 – 52: PN 16 and PN 25 with round flanges according to ISO 2531 and ISO 7005

Materials

Helix2.0-VE 2, 4, 6, 10, 16:

Standard version

- Impellers, stage housings and guide vanes made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4301 (AISI 304)

- Baseplate and lantern in EN-GJL-250 (cataphoretic coated)

- Shaft made of stainless steel 1.4301 (AISI 304) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Impellers, stage housings and guide vane apparatuses made of stainless steel 1.4404 (316L)

- Pump housing made of stainless steel 1.4404 (316L)

- Shaft made of stainless steel 1.4404 (316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (316L)

- O-ring of FKM (EPDM gasket on request)

- Jacket pipe made of stainless steel 1.4404 (316L)

Standard version

- Stage housings, impellers, guide vane apparatuses made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4301 (AISI 304) or cataphoretic-coated grey cast iron EN-GJL 250, loose flanges made of EN-GJS 400 for Helix2.0-VE 36-52.

- Shaft made of stainless steel 1.4057 (AISI 431)

- Sleeve under the mechanical seal 1.4404 (316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Stage housings, impellers, and guide vane apparatuses made of stainless steel 1.4404 (316L)

- Pump housing: all parts which come in contact with the media are made of cast stainless steel 1.4409 (316L); loose flanges of cataphoretic-coated grey cast iron EN-GJL 250 for Helix2.0-VE 22 / EN-GJS 400 for Helix2.0-VE 36-52.

- Baseplate made of stainless steel 1.4301 (AISI 304)

- Shaft made of stainless steel 1.4404 (316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (316L)

- O-ring of FKM (EPDM gasket on request)

- Pressure shroud made of stainless steel 1.4404 (316L)

- Helix2.0-VE high-pressure multistage centrifugal pump

- Installation and operating instructions

- Helix2.0-VE 2 – 16 (version PN16 with oval flanges): Counter flanges made of stainless steel with corresponding screws, nuts and gaskets

General functions

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions:

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions:

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions:

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions:

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values