Existing pump - Multistage

Replacement pump Exchange sheet

Comment

Product information

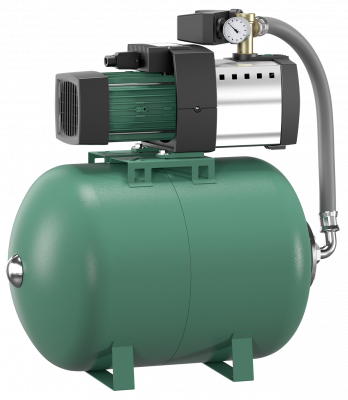

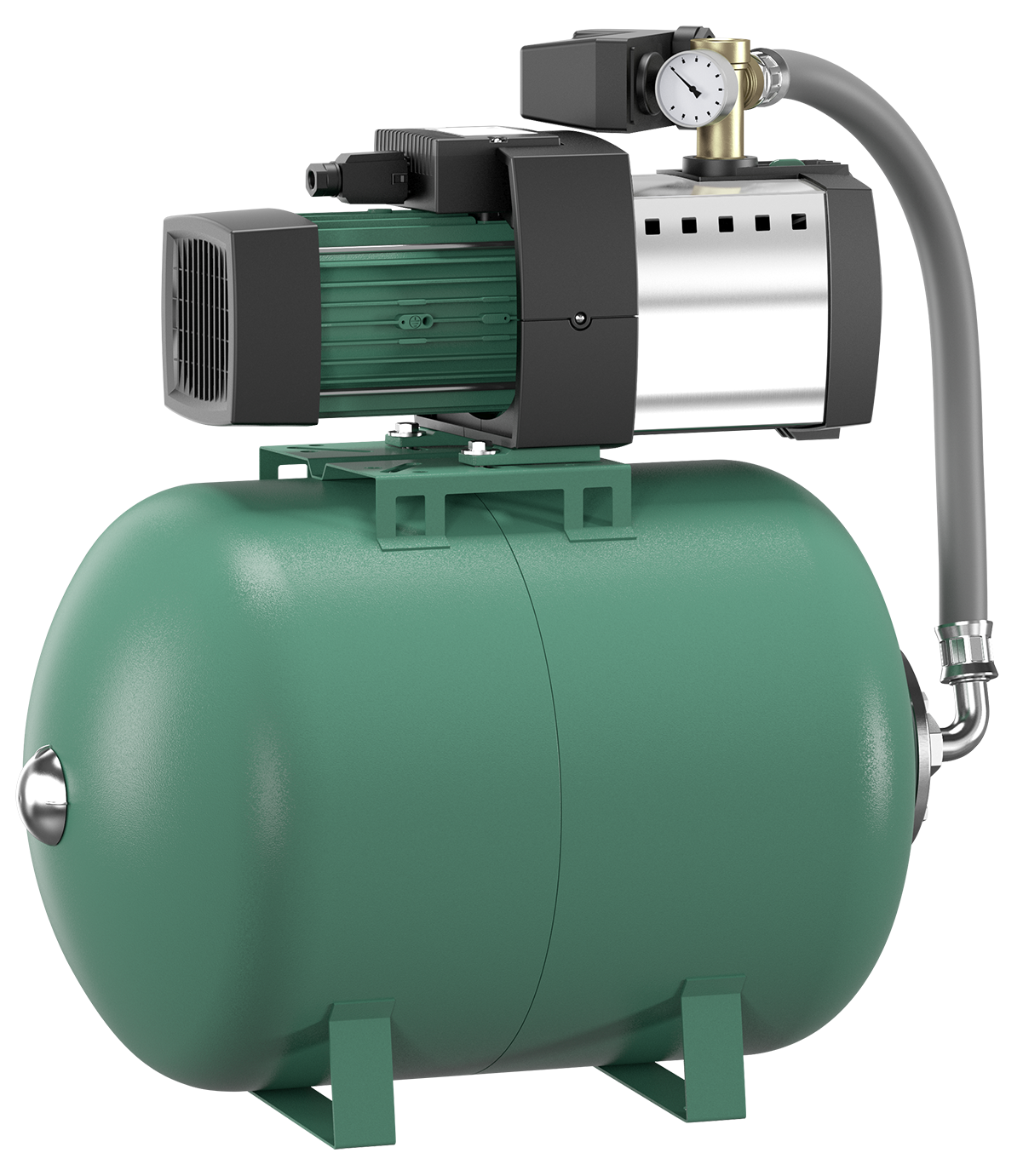

HiMulti 3 H50-45 P 1~

Your advantages

- Simple: Plug & Pump system

- Efficient: Highly efficient hydraulics, low electricity consumption and very compact thanks to motor optimisation

- Automatically functioning system, avoidance of fluid hammers thanks to pressure switching and diaphragm pressure vessel

- Low-noise: Noise level between 56 dB(A) and 64 dB(A)

Water-supply system with diaphragm pressure vessel in non-self-priming version (HiMulti 3 H) or self-priming version (HiMulti 3 H P).

Application

- Water supply (drinking water certification in accordance with ACS)

- Sprinkling

- Irrigation and spraying

- Rainwater utilisation

- Directly flanged motor

- Pressure switch

- Diaphragm pressure vessel (with replaceable diaphragm)

- Connection cable with plug

- Thermal motor protection switch

- Pump

- Pressure switch

- Pressure gauge

- Diaphragm pressure vessel (contents 50 l or 100 l)

- Pressure hose with steel housing and screwed connection

- 1 piece plastic connector with seal for manual connection to the inlet pipe

- Wilo-Connector (electrical quick connector)

- Installation and operating instructions

- Mains connection: 1~230 V, 50 Hz

- Perm. fluid temperature: 0 °C to +40 °C (+55 °C for 10 min)

- Perm. ambient temperature: -15 °C to +40 °C

- Permissible storage temperature: -30 °C to +60 °C

- Max. permissible operating pressure: 8 bar

- Max. permissible inlet pressure: 3 bar

- Tank volume: 50 or 100 l

- Configuration range for the pressure switch: 1-5 bar

- Protection class IP 54

- Pipe connection on pressure side: Rp1

- Pipe connection on suction side: Rp1

- Pump housing in Technopolymer with ACS, WRAS and KTW drinking certifications

- Impellers and stage casing made of Noryl 30% GF with drinking water certification in accordance with ACS, WRAS and KTW

- Pump cover and shaft made of stainless steel

- Mechanical seal made of ceramic/carbon