Existing pump - Multistage

Replacement pump Exchange sheet

Comment

Product information

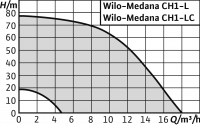

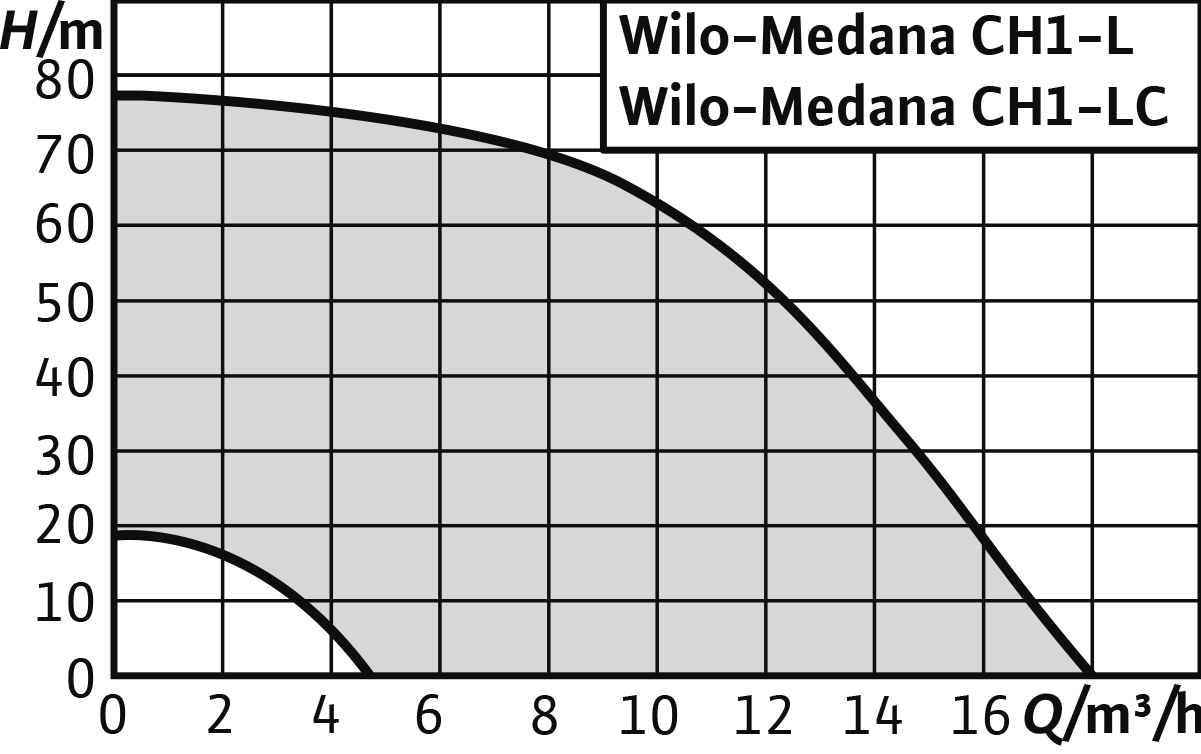

Medana CH1-L.404-1 3~

Your advantages

- High efficiency thanks to high hydraulic output

- Quick and easy commissioning/maintenance thanks to large openings for filling and draining pumps

- Highly reliable and robust with low noise emissions thanks to neck ring and corrosion-resistant lantern with cataphoretic coating

- Suitable for use in ambient temperatures of up to 50 °C and expanded field of application especially for system integration

- Suitable for drinking water applications

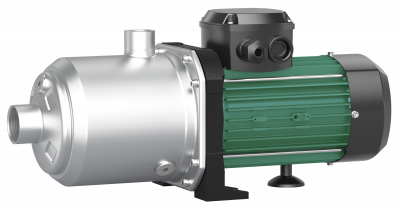

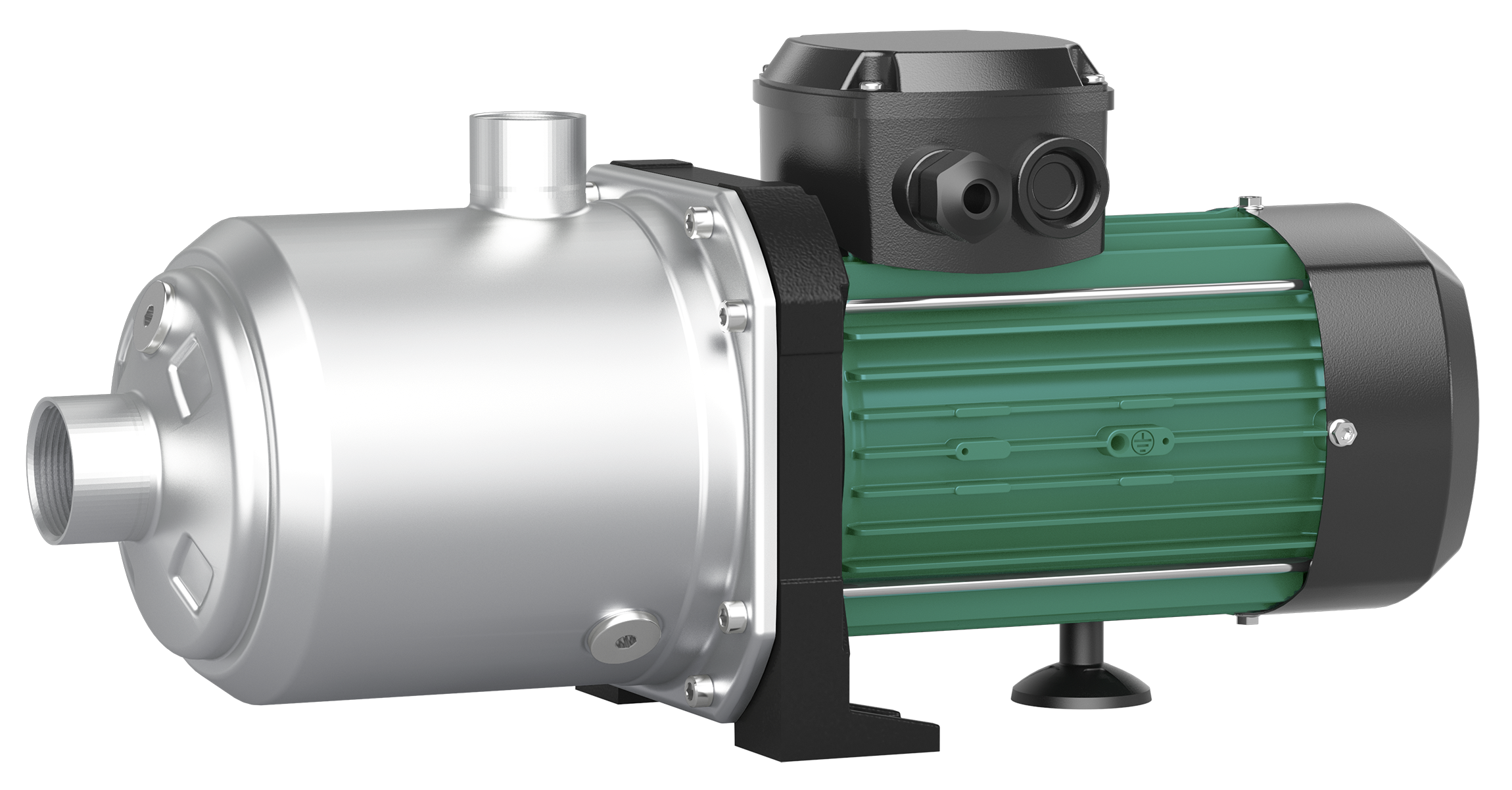

Thanks to its drinking water certificate, the Wilo-Medana CH1-L is also suitable for drinking water applications. The non self-priming, multistage pump reaches maximum hydraulic output. Its compact and robust design with corrosion-resistant components and suitability for use in ambient temperatures up to 50 °C offer a large field of application for pump integration in larger systems.

Construction

Non self-priming horizontal multistage pump.

Application

- Water distribution and boosting

- Irrigation

- Industrial process

- Stainless steel in monobloc design

- Threaded connection

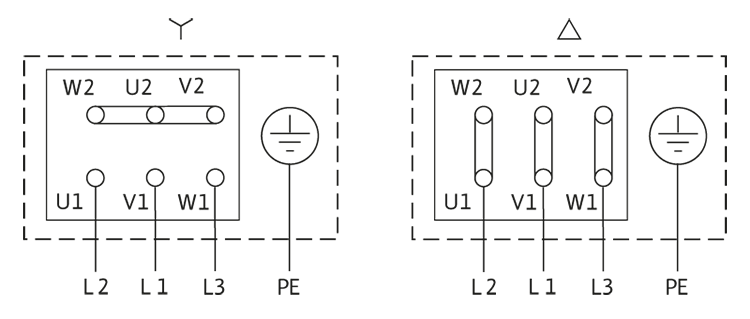

- Single-phase or three-phase AC motor

- Single-phase AC motor equipped with built-in thermal motor protection (with automatic restart)

- Pump

- Installation and operating instructions

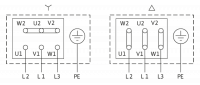

- Mains connection: 1~230 V (±10 %), 50Hz

- Mains connection: 3~230 V-400 V (±10 %), 50 Hz; 265-460 V (±10 %), 60 Hz

- Fluid temperature: -20 to +120 °C (EPDM), -20 to +90°C (FKM)

- Max. operating pressure: 10 bar

- Max. inlet pressure: 6 bar

- Protection class: IPX5

- Nominal diameters of pipe connections: from G1” to G2”depending on typ

- Impellers, stage chambers and pump housing made of 1.4301/1.4404 stainless steel

- Shaft 1.4301 or 1.4404 stainless steel

- Seal EPDM/FKM (Viton)

- Mechanical seal: EPDM version: B-carbon/silicon carbide; FKM version: B-carbon/silicon carbide

- Bearing tungsten carbide/aluminum oxide

- Pump base aluminum