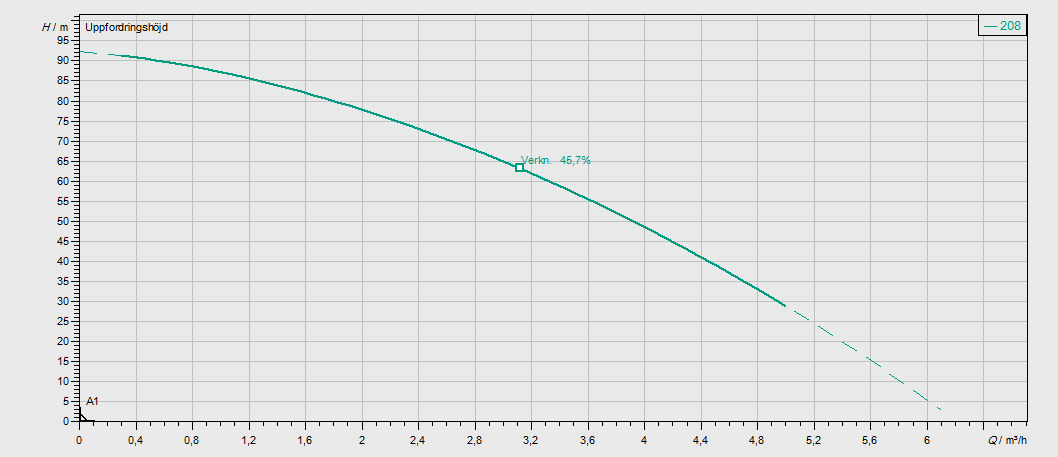

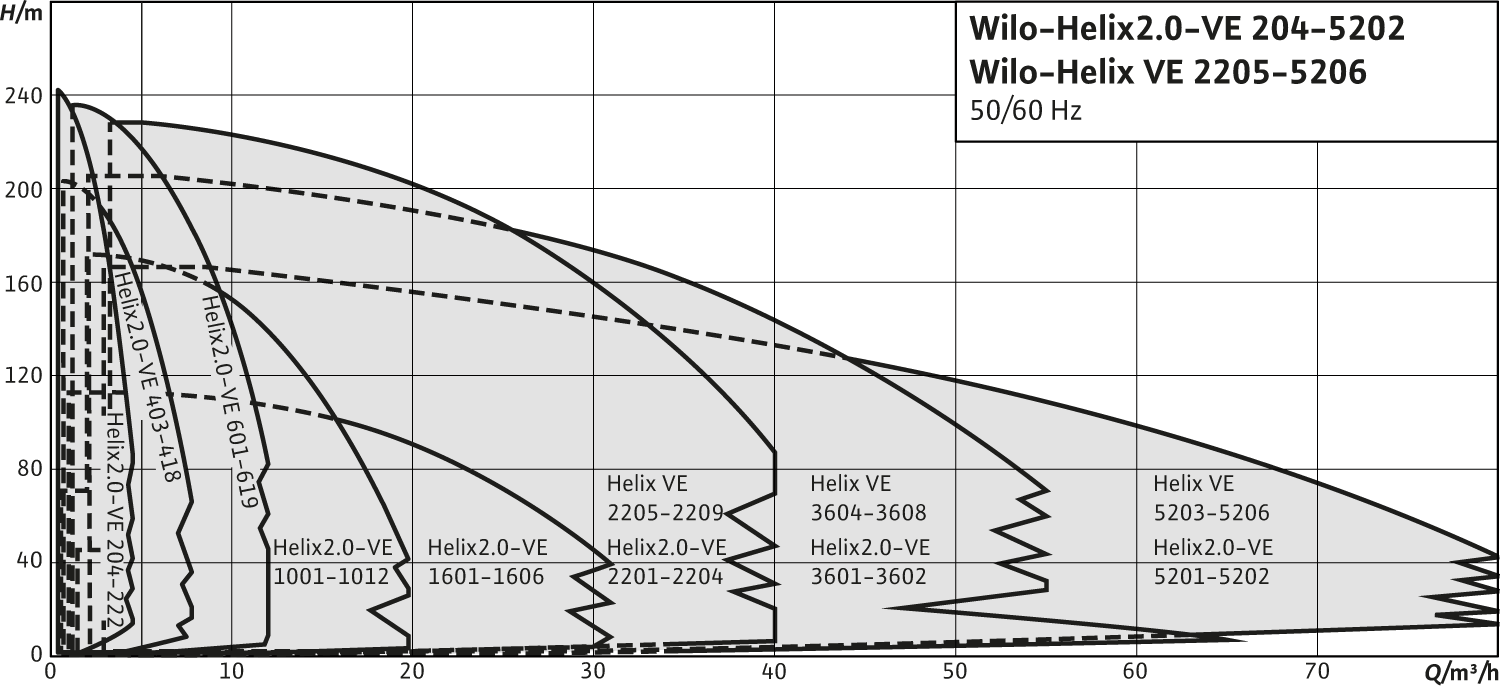

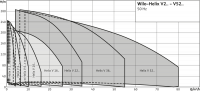

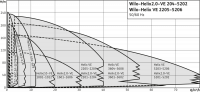

Existing pump - Multistage Pump curve

Replacement pump Exchange sheet

Comment

Product information

Helix V 410-1/16/E/KS/400-50

Your advantages

- Efficiency-optimised, laser-welded 2D/3D hydraulics, flow and degassing optimised

- Corrosion-resistant impellers, guide vanes and stage housings

- Flow and NPSH-optimised pump housing

- Maintenance-friendly design with particularly robust coupling guard

- Drinking water approval for pumps with parts that come in contact with the fluid made of stainless steel (EPDM version)

Non-self-priming, high-efficiency multistage high-pressure centrifugal pump in vertical design with in-line connections.

Application

- Water supply and pressure boosting

- Industrial circulation systems

- Process water

- Closed cooling circuits

- Fire extinguishing systems

- Washing systems

- Irrigation

- Corrosion-resistant impellers, guide vanes and stage housings

- Helix V high-pressure multistage centrifugal pump

- Installation and operating instructions

- Helix V 2 – 16 (version PN16 with oval flanges): counter flanges made of stainless steel with the corresponding screws, nuts and gaskets

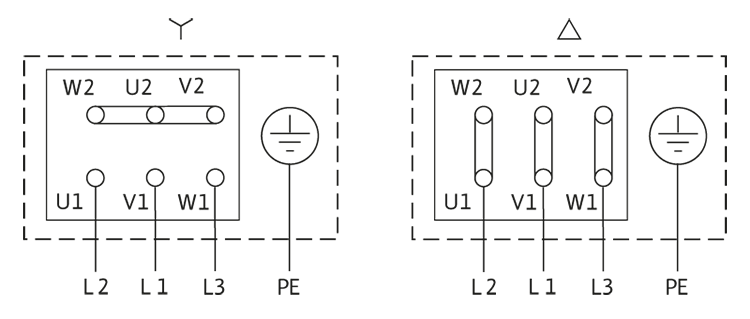

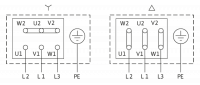

- Electrical connection:

- 3~400 V (±10 %), 50 Hz

- ≤ 4 kW 230 V/ 400 V; Δ/Y

- > 4 kW 400 V/ 690 V; Δ/Y

- 1~ 230 V (±10 %), 50 Hz, only Wilo-Helix V 2, 4, 6, 10

- Fluid temperature range:

- Helix V 2 – 16 (EPDM): -30 to 120 °C (130 °C on request)

- Helix V 2 – 16 for aggressive media (FKM): -15 to 90 °C

- Helix V22 – 52 (EPDM): -20 to 120 °C (130 °C on request)

- Helix V22 – 52 for aggressive media (FKM): -15 to 90 °C

- Max. operating pressure: 16/25/30 bar

- Max. inlet pressure of 10 bar

- Protection class: IP 55

- Max. ambient temperature: -15 °C – +50 °C (extended temperature ranges on request)

- Available versions:

- Helix V 2 – 16: PN 16 with oval flanges, PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005 (Victaulic coupling on request)

- Helix V 22 – 52: PN 16/PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005

Helix V 2, 4, 6, 10, 16:

Standard version

- Impellers, stage housings and guide vanes made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4301 (AISI 304)

- Baseplate and lantern in EN-GJL-250 (cataphoretic coated)

- Shaft made of stainless steel 1.4301 (AISI 304) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Impellers, stage housings and guide vane apparatuses of stainless steel 1.4404 (AISI 316L)

- Pump housing made of stainless steel 1.4404 (AISI 316L)

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of FKM (EPDM gasket on request)

- Jacket pipe made of stainless steel 1.4404 (AISI 316L)

Standard version

- Stage housings, impellers, guide vane apparatuses made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4308 (AISI 304) or cataphoretic-coated grey cast iron EN-GJL 250, loose flanges made of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

- Shaft made of stainless steel 1.4057 (AISI 431)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Stage housings, impellers, and guide vane apparatuses made of stainless steel 1.4404 (AISI 316L)

- Pump housing: all parts which come in contact with the media are made of cast stainless steel 1.4409 (AISI 316L); loose flanges of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

- Baseplate made of stainless steel 1.4301 (AISI 304)

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of FKM (EPDM gasket on request)

- Pressure shroud made of stainless steel 1.4404 (AISI 316L)

Description/construction

- Pumps can be adapted to specific circumstances on request (e.g. motor protection, IE4 motor efficiency class, VdS certified Wilo-Helix pumps, ATEX, extended ambient temperature range).

- The Helix series is also available with an integrated frequency converter.

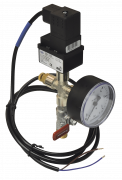

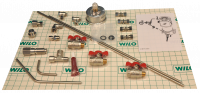

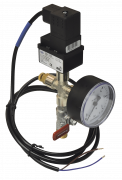

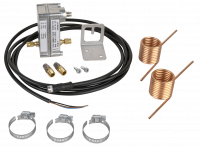

Bypass kit for continuous ventilation of Helix pumps in series 2/ 4 / 6 / 10 / 16.

- Comes with pressure gauge.

- Suitable to use for all types of self and normal suction systems, e.g. irrigation, cooling towers etc.

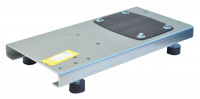

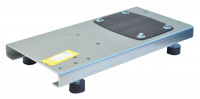

Foot plate is for mounting on foundation or floor. It fits all pumps in the Helix series with a maximum engine power of 5.5 kW.

- Pump housing (pump) is screwed into the foot plate with four bolts (dimension M8 or M10, depending on the pump size - see pump catalogue leaf), recommended length of bolt 40-70 mm.

- The foot plate is equipped with vibration dampers, one in each corner.

- Made of stainless steel.

- Dimensions: 405 x 90 x 405 mm (W x H x D).

The safety valve protects the system against overpressure when using water supply and pressure relief systems.

- Activation pressure 10% above the factory preset pressure.

- Allowed media - water without abrasive particles.

- Media temperature max 130 ° C.

- House made of plaster / brass.

- Seal made by Perbunan / EPDM.

The safety valve protects the system against overpressure when using water supply and pressure relief systems.

- Activation pressure 10% above the factory preset pressure.

- Allowed media - water without abrasive particles.

- Media temperature max 130 ° C.

- House made of plaster / brass.

- Seal made by Perbunan / EPDM.

Connection to the joint tubing Rp ¼' threaded bushing.

The pressure switch locks at 1.0 bar and enables at 1.3 bar (factory works setting in accordance with DIN 1988).

The factory settings cannot be modified.

Replacement pump Exchange sheet

Comment

Product information

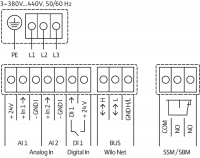

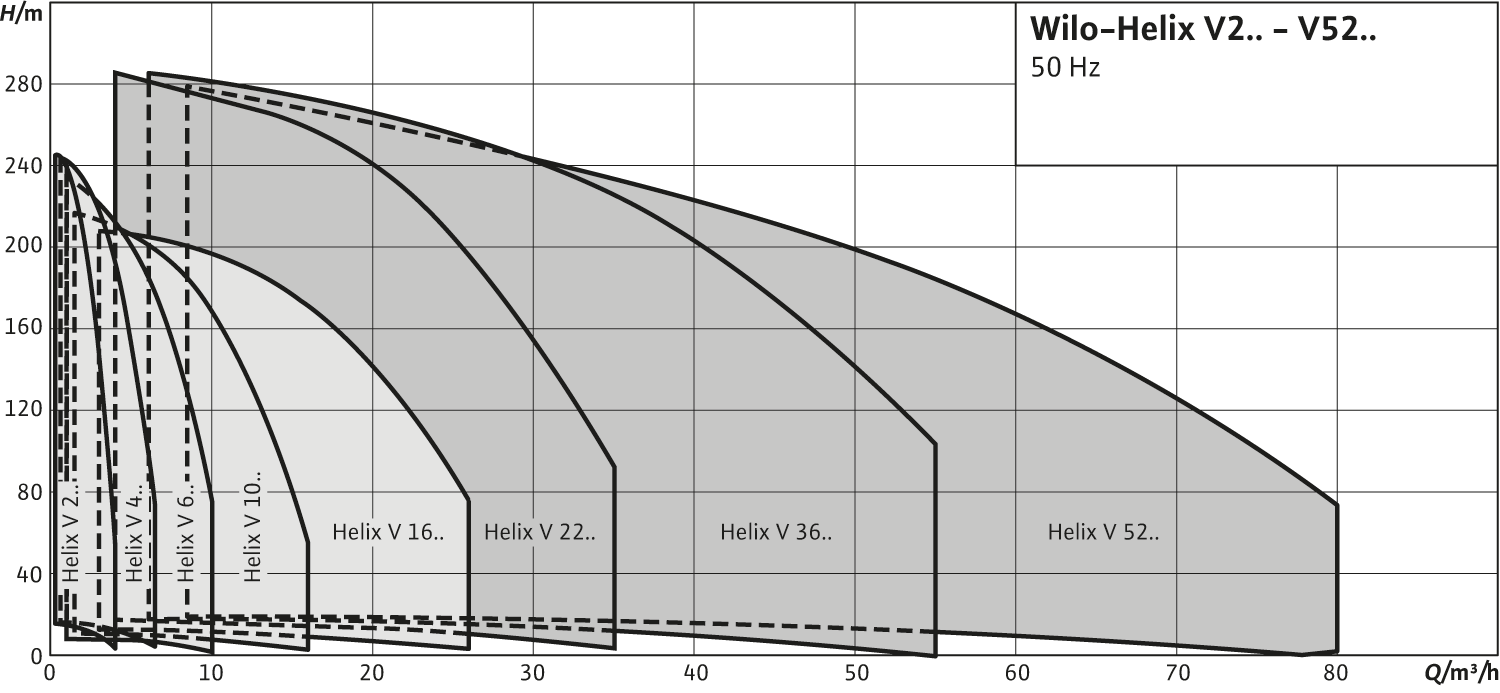

Helix2.0-VE 208-1/16/E/S/3

Design

Highly efficient, non-self-priming high-pressure multistage centrifugal pump in vertical design with in-line connections, equipped with electronically controlled EC motor of energy efficiency class IE5 in accordance with IEC 60034-30-2.

Application

- Water supply and pressure boosting

- Industrial circulation systems

- Process water

- Closed cooling circuits

- Heating

- Washing systems

- Irrigation

- 2” colored LCD display

- Wilo Green Button Technology and soft button with return function for menu navigation and pump setting

- Green LED indicates pump status

- Blue LED indicates that pump is influenced externally via an interface

- Impellers, guide vanes and stage housings made of corrosion-resistant material

- Constant pressure p-c

- Constant differential pressure ∆p-c

- Variable differential pressure ∆p-v

- Constant speed n-c

- PID control

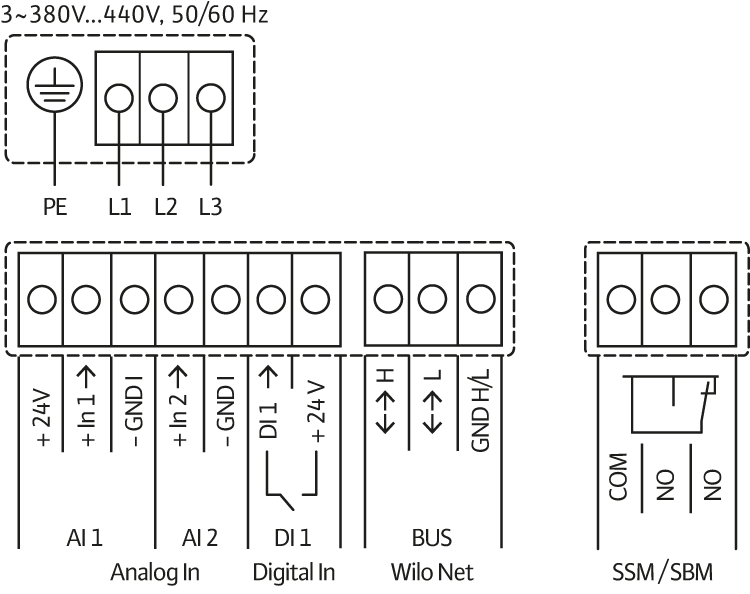

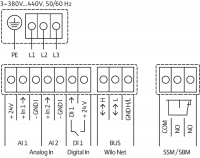

- IN (AI 1): Input sensor signal 4-20 mA, 0-10 V, 0-20 mA or 2-10 V

- IN (AI 2): Input setpoint 0-20 mA, 0-10 V, 4-20 mA, 2-10 V or input sensor signal 4-20 mA, 0-10 V, 0-20 mA or 2-10 V

- Extern off

- Lack of water detection by binary input

- Max. pressure limit detection

- Min. pressure limit detection

- Lack of water detection by suction sensor

- Zero flow test (open loop)

- No-Flow Stop (closed loop)

- Dry running detection

- Volume flow calculation by using differential pressure sensor

- Pump kick

- Error and warning codes

- Overload protection

- Access lock

- Plug-in position for Wilo CIF-modules PLR, LON, BACnet MS/TP, Modbus RTU, CANopen, Ethernet Multi-protocol (Modbus TCP, BACnet/IP) for connection to the building automation

- Main/standby operation

- Pump cycling main/standby operation after 24 hours or automatic fault-actuated switchover

- Wired connection via Wilo Net

Electrical connection:

- 3~ 380 V …440 V (+/- 10%) 50 Hz/60 Hz

- TN, TT, IT

- Helix2.0-VE 2 – 16 (EPDM): -30 to 120 °C (130 °C on request)

- Helix2.0-VE 2 – 16 for aggressive media (FKM): -15 to 90 °C

- Helix2.0-VE – 52 (EPDM): -20 to 120 °C (130 °C on request)

- Helix2.0-VE 22 – 52 for aggressive media (FKM): -15 to 90 °C (-30 to 120 °C with EPDM gasket on request)

Protection class: IP 55

Max. ambient temperature: +50°C

Available versions:

Helix2.0-VE 2 – 16: PN 16 with oval flanges, PN 25 with round flanges according to ISO 2531 and ISO 7005 (Victaulic coupling on request)

Helix2.0-VE 22 – 52: PN 16 and PN 25 with round flanges according to ISO 2531 and ISO 7005

Materials

Helix2.0-VE 2, 4, 6, 10, 16:

Standard version

- Impellers, stage housings and guide vanes made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4301 (AISI 304)

- Baseplate and lantern in EN-GJL-250 (cataphoretic coated)

- Shaft made of stainless steel 1.4301 (AISI 304) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Impellers, stage housings and guide vane apparatuses made of stainless steel 1.4404 (316L)

- Pump housing made of stainless steel 1.4404 (316L)

- Shaft made of stainless steel 1.4404 (316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (316L)

- O-ring of FKM (EPDM gasket on request)

- Jacket pipe made of stainless steel 1.4404 (316L)

Standard version

- Stage housings, impellers, guide vane apparatuses made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4301 (AISI 304) or cataphoretic-coated grey cast iron EN-GJL 250, loose flanges made of EN-GJS 400 for Helix2.0-VE 36-52.

- Shaft made of stainless steel 1.4057 (AISI 431)

- Sleeve under the mechanical seal 1.4404 (316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Stage housings, impellers, and guide vane apparatuses made of stainless steel 1.4404 (316L)

- Pump housing: all parts which come in contact with the media are made of cast stainless steel 1.4409 (316L); loose flanges of cataphoretic-coated grey cast iron EN-GJL 250 for Helix2.0-VE 22 / EN-GJS 400 for Helix2.0-VE 36-52.

- Baseplate made of stainless steel 1.4301 (AISI 304)

- Shaft made of stainless steel 1.4404 (316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (316L)

- O-ring of FKM (EPDM gasket on request)

- Pressure shroud made of stainless steel 1.4404 (316L)

- Helix2.0-VE high-pressure multistage centrifugal pump

- Installation and operating instructions

- Helix2.0-VE 2 – 16 (version PN16 with oval flanges): Counter flanges made of stainless steel with corresponding screws, nuts and gaskets

Bypass kit for continuous ventilation of Helix pumps in series 2/ 4 / 6 / 10 / 16.

- Comes with pressure gauge.

- Suitable to use for all types of self and normal suction systems, e.g. irrigation, cooling towers etc.

Foot plate is for mounting on foundation or floor. It fits all pumps in the Helix series with a maximum engine power of 5.5 kW.

- Pump housing (pump) is screwed into the foot plate with four bolts (dimension M8 or M10, depending on the pump size - see pump catalogue leaf), recommended length of bolt 40-70 mm.

- The foot plate is equipped with vibration dampers, one in each corner.

- Made of stainless steel.

- Dimensions: 405 x 90 x 405 mm (W x H x D).

The safety valve protects the system against overpressure when using water supply and pressure relief systems.

- Activation pressure 10% above the factory preset pressure.

- Allowed media - water without abrasive particles.

- Media temperature max 130 ° C.

- House made of plaster / brass.

- Seal made by Perbunan / EPDM.

The IR-Stick in combination with the supplied Wilo software (CD-ROM), makes it possible to read out and save data records for pumps as well as send previously defined pump settings.

- IR carrier frequency: 33 kHz / 455 kHz

- Software upgrade: via USB

- Inaccessibly installed pumps

- Quick configuration of pumps

- Extensive operating information

- Detailed fault diagnosis

- Statistical functions

- Special settings/control modes for special requirements

- Protection against unauthorised access

- Archiving of pump data sets

Connection to the joint tubing Rp ¼' threaded bushing.

The pressure switch locks at 1.0 bar and enables at 1.3 bar (factory works setting in accordance with DIN 1988).

The factory settings cannot be modified.

General functions

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions:

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions:

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions:

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions:

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.

Replacement pump Exchange sheet

Comment

Product information

Helix2.0-VE 208-1/16/E/KS/3

Design

Highly efficient, non-self-priming high-pressure multistage centrifugal pump in vertical design with in-line connections, equipped with electronically controlled EC motor of energy efficiency class IE5 in accordance with IEC 60034-30-2.

Application

- Water supply and pressure boosting

- Industrial circulation systems

- Process water

- Closed cooling circuits

- Heating

- Washing systems

- Irrigation

- 2” colored LCD display

- Wilo Green Button Technology and soft button with return function for menu navigation and pump setting

- Green LED indicates pump status

- Blue LED indicates that pump is influenced externally via an interface

- Impellers, guide vanes and stage housings made of corrosion-resistant material

- Constant pressure p-c

- Constant differential pressure ∆p-c

- Variable differential pressure ∆p-v

- Constant speed n-c

- PID control

- IN (AI 1): Input sensor signal 4-20 mA, 0-10 V, 0-20 mA or 2-10 V

- IN (AI 2): Input setpoint 0-20 mA, 0-10 V, 4-20 mA, 2-10 V or input sensor signal 4-20 mA, 0-10 V, 0-20 mA or 2-10 V

- Extern off

- Lack of water detection by binary input

- Max. pressure limit detection

- Min. pressure limit detection

- Lack of water detection by suction sensor

- Zero flow test (open loop)

- No-Flow Stop (closed loop)

- Dry running detection

- Volume flow calculation by using differential pressure sensor

- Pump kick

- Error and warning codes

- Overload protection

- Access lock

- Plug-in position for Wilo CIF-modules PLR, LON, BACnet MS/TP, Modbus RTU, CANopen, Ethernet Multi-protocol (Modbus TCP, BACnet/IP) for connection to the building automation

- Main/standby operation

- Pump cycling main/standby operation after 24 hours or automatic fault-actuated switchover

- Wired connection via Wilo Net

Electrical connection:

- 3~ 380 V …440 V (+/- 10%) 50 Hz/60 Hz

- TN, TT, IT

- Helix2.0-VE 2 – 16 (EPDM): -30 to 120 °C (130 °C on request)

- Helix2.0-VE 2 – 16 for aggressive media (FKM): -15 to 90 °C

- Helix2.0-VE – 52 (EPDM): -20 to 120 °C (130 °C on request)

- Helix2.0-VE 22 – 52 for aggressive media (FKM): -15 to 90 °C (-30 to 120 °C with EPDM gasket on request)

Protection class: IP 55

Max. ambient temperature: +50°C

Available versions:

Helix2.0-VE 2 – 16: PN 16 with oval flanges, PN 25 with round flanges according to ISO 2531 and ISO 7005 (Victaulic coupling on request)

Helix2.0-VE 22 – 52: PN 16 and PN 25 with round flanges according to ISO 2531 and ISO 7005

Materials

Helix2.0-VE 2, 4, 6, 10, 16:

Standard version

- Impellers, stage housings and guide vanes made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4301 (AISI 304)

- Baseplate and lantern in EN-GJL-250 (cataphoretic coated)

- Shaft made of stainless steel 1.4301 (AISI 304) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Impellers, stage housings and guide vane apparatuses made of stainless steel 1.4404 (316L)

- Pump housing made of stainless steel 1.4404 (316L)

- Shaft made of stainless steel 1.4404 (316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (316L)

- O-ring of FKM (EPDM gasket on request)

- Jacket pipe made of stainless steel 1.4404 (316L)

Standard version

- Stage housings, impellers, guide vane apparatuses made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4301 (AISI 304) or cataphoretic-coated grey cast iron EN-GJL 250, loose flanges made of EN-GJS 400 for Helix2.0-VE 36-52.

- Shaft made of stainless steel 1.4057 (AISI 431)

- Sleeve under the mechanical seal 1.4404 (316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Stage housings, impellers, and guide vane apparatuses made of stainless steel 1.4404 (316L)

- Pump housing: all parts which come in contact with the media are made of cast stainless steel 1.4409 (316L); loose flanges of cataphoretic-coated grey cast iron EN-GJL 250 for Helix2.0-VE 22 / EN-GJS 400 for Helix2.0-VE 36-52.

- Baseplate made of stainless steel 1.4301 (AISI 304)

- Shaft made of stainless steel 1.4404 (316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (316L)

- O-ring of FKM (EPDM gasket on request)

- Pressure shroud made of stainless steel 1.4404 (316L)

- Helix2.0-VE high-pressure multistage centrifugal pump

- Installation and operating instructions

- Helix2.0-VE 2 – 16 (version PN16 with oval flanges): Counter flanges made of stainless steel with corresponding screws, nuts and gaskets

Bypass kit for continuous ventilation of Helix pumps in series 2/ 4 / 6 / 10 / 16.

- Comes with pressure gauge.

- Suitable to use for all types of self and normal suction systems, e.g. irrigation, cooling towers etc.

Foot plate is for mounting on foundation or floor. It fits all pumps in the Helix series with a maximum engine power of 5.5 kW.

- Pump housing (pump) is screwed into the foot plate with four bolts (dimension M8 or M10, depending on the pump size - see pump catalogue leaf), recommended length of bolt 40-70 mm.

- The foot plate is equipped with vibration dampers, one in each corner.

- Made of stainless steel.

- Dimensions: 405 x 90 x 405 mm (W x H x D).

The safety valve protects the system against overpressure when using water supply and pressure relief systems.

- Activation pressure 10% above the factory preset pressure.

- Allowed media - water without abrasive particles.

- Media temperature max 130 ° C.

- House made of plaster / brass.

- Seal made by Perbunan / EPDM.

The IR-Stick in combination with the supplied Wilo software (CD-ROM), makes it possible to read out and save data records for pumps as well as send previously defined pump settings.

- IR carrier frequency: 33 kHz / 455 kHz

- Software upgrade: via USB

- Inaccessibly installed pumps

- Quick configuration of pumps

- Extensive operating information

- Detailed fault diagnosis

- Statistical functions

- Special settings/control modes for special requirements

- Protection against unauthorised access

- Archiving of pump data sets

Connection to the joint tubing Rp ¼' threaded bushing.

The pressure switch locks at 1.0 bar and enables at 1.3 bar (factory works setting in accordance with DIN 1988).

The factory settings cannot be modified.

General functions

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions:

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions:

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions:

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

General functions:

Serial, digital interface for connection to building automation (BA) for the transfer of data points as:

- Control commands to the pump

- Messages from the pump

- Process values

The sensor measures the differential pressure between the suction ports and discharge ports to the pipes, and converts this into an electrical signal 4-20 mA, which is used by the frequency converter to regulate the pressure of the pump. The value of the output current is proportional to the differential pressure.