Existing pump - Multistage

Replacement pump Exchange sheet

Comment

Product information

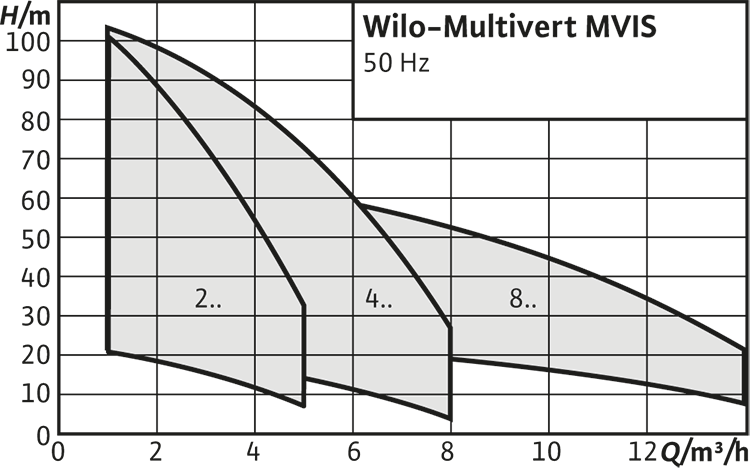

MVIS 805

Your advantages

- Glandless pump technology

- Virtually noiseless operation (up to 20 dB [A] quieter than conventional pumps)

- Space-saving, compact design

- Virtually maintenance free thanks to a design which does not feature any mechanical seals

- Drinking water approval for all components that come in contact with the fluid (EPDM version)

Non-self-priming multistage pump with glandless pump motor.

Application

- Water supply and pressure boosting systems

- Non self-priming vertical high-pressure multistage centrifugal pump of in-line design

- Three-phase current motor in glandless pump version

- Hydraulic connection with oval flanges PN 16

- Wilo-Multivert MVIS high-pressure multistage centrifugal pump

- Stainless steel counter flanges Rp 1 to Rp 1½ with the corresponding screws, nuts and gaskets

- Installation and operating instructions

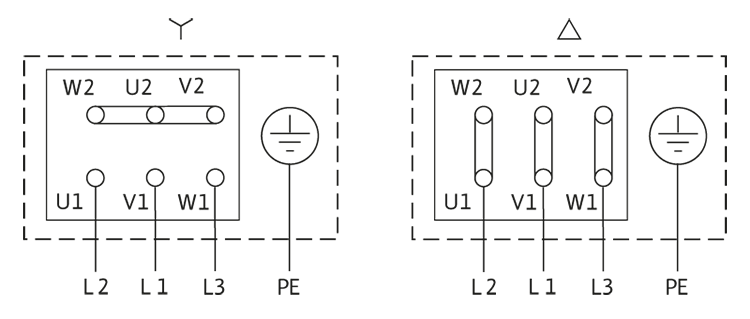

- Mains connection 3~ 230 V (±10%), 50 Hz (Δ), 400 V (±10%), 50 Hz (Y)

- Fluid temperature of -15 to +50 °C

- Ambient temperature of -15 to +40 °C

- Max. operating pressure 16 bar

- Max. inlet pressure 10 bar

- Protection class IP44

- Nominal diameters of pipe connections Rp 1, Rp 1¼ or Rp 1½, depending on the version

- Impellers made of 1.4301 (AISI304) stainless steel

- Stage chambers made of 1.4301 (AISI304) stainless steel

- Pump housing made of 1.4301 (AISI304) stainless steel

- Shaft 1.4122 stainless steel

- EPDM seal

- Housing lower section made of 1.4301 (AISI304) stainless steel

- Pressure shroud made of 1.4301 (AISI304) stainless steel

- Pump support foot made of EN-GJL-250